That’s a relief…

Vibration Stress Relief – is it a suitable alternative to thermal stress relief in machine tool manufacturing? By Kasra Mehraky

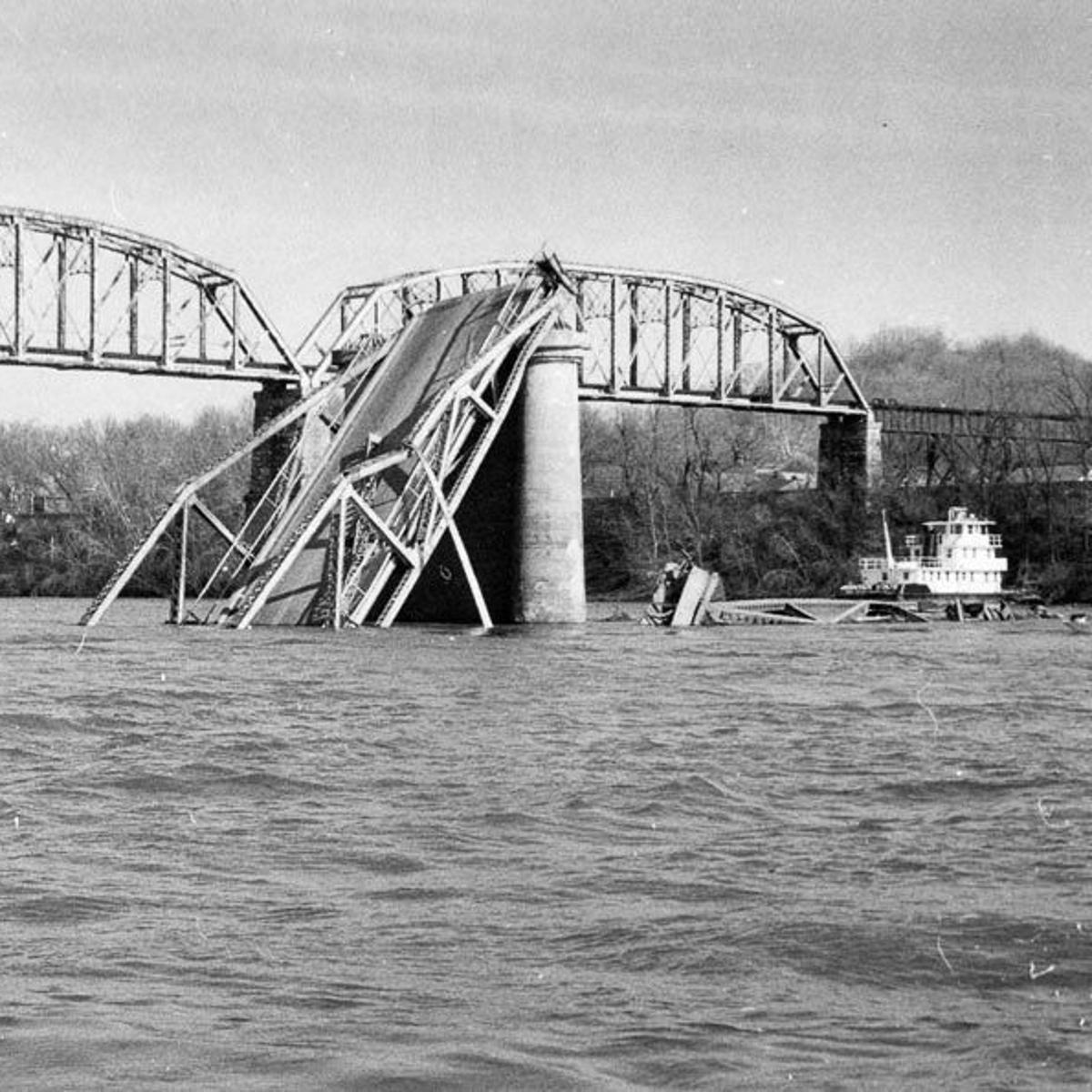

On the 15th of December 1967, a bridge called Silver Bridge connecting Point Pleasant, West Virginia with and Gallipolis in Ohio collapsed during rush hour and sadly, 46 people were killed. It was due to a failure in an eyebar in a suspension chain that was slightly defective. The eyebar links were castings that showed high levels of residual stress.

Residual stresses are created during most manufacturing processes, including casting, welding and machining. If not relieved properly, these stresses can bring about destructive results over time, as they affect some of the mechanical properties of the component such as Ultimate Stress and Fatigue Strength. This can also cause distortion. Gradual relief of residual stresses can result in distortion of machine tool structures and a deviation from the nominal accuracy. This also increases wear and shortens the life span of the machine and its components.

To alleviate the negative effects of residual stresses, manufacturers use different methods to relieve them This is done either after manufacturing processes or in between them before the component is used. Among stress relief methods that exist today, thermal stress relief and ageing are the most common. Despite its guaranteed effectiveness, thermal stress relief has several disadvantages such as the possibility of distortion and discolouration, limited application to heat-treatable metals, changes in some mechanical properties, including hardness and toughness, high cost and high pollution of the environment. Another common stress relief method is ageing, which is extremely time-consuming despite its absolute effectiveness, making it a less logical option in many cases.

In this article, I intend to introduce a lesser-known method and discuss its benefits as an alternative to thermal stress relief and ageing as well as its challenges. Vibration Stress Relief (VSR) is an alternative up-to-date method for relieving residual stresses using forced resonance or sub-resonance vibrations. Forced vibrations at resonance frequencies and certain sub-resonance frequencies introduce energy into the crystalline structure of components and relieve residual stresses by affecting dislocations. This method has existed for years; therefore, both the process and the equipment have evolved as a result of the research conducted in this area. Among the two VSR methods that currently exist, sub-resonance VSR seems to be more efficient, as it minimises energy consumption and the possibility of fatigue. This method also has more reliability as it is used by Bonal, an American company and their Meta-Lax system, one of the most famous manufacturers of VSR equipment.

Sub-Resonance stress relief is done in three stages. First, vibrations are induced on the component until the first specific sub-resonant frequency is reached. Then, the frequency is kept the same until the amplitude of the response is stable. Lastly, the previous steps are repeated until the resonance frequency does not change anymore. In some cases, this process is also done for the second and third sub-resonance frequencies to ensure sufficient stress relief.

VSR has recently caught the attention of many manufacturers due to its benefits over the other methods. On the contrary to thermal stress relief, VSR does not cause discolouration, scaling or distortion and maintains the original mechanical properties of the part. It is also much less expensive than thermal treatment since the equipment can be purchased for on-site application, thus omitting the thermal treatment equipment costs such as the oven or transportation of the part to a service provider and the costs of the process itself. Also, VSR is much less time and energy consuming than thermal treatment, since the process itself is shorter, the transportation time is omitted and it can be applied to assembled parts without the need to take them apart. This stress relief method is also very versatile, allowing for stress relief of non-heat-treatable material, bulky parts, hardened parts, components with variable thickness and components with the ground or polished surfaces. Furthermore, VSR can be reapplied multiple times and also done in between or during several manufacturing processes such as welding or rough machining passes to achieve satisfactory results in cases that residual stresses are accumulated during several consecutive manufacturing procedures.

VSR has recently caught the attention of many manufacturers due to its benefits over the other methods. On the contrary to thermal stress relief, VSR does not cause discolouration, scaling or distortion and maintains the original mechanical properties of the part. It is also much less expensive than thermal treatment since the equipment can be purchased for on-site application, thus omitting the thermal treatment equipment costs such as the oven or transportation of the part to a service provider and the costs of the process itself. Also, VSR is much less time and energy consuming than thermal treatment, since the process itself is shorter, the transportation time is omitted and it can be applied to assembled parts without the need to take them apart. This stress relief method is also very versatile, allowing for stress relief of non-heat-treatable material, bulky parts, hardened parts, components with variable thickness and components with the ground or polished surfaces. Furthermore, VSR can be reapplied multiple times and also done in between or during several manufacturing processes such as welding or rough machining passes to achieve satisfactory results in cases that residual stresses are accumulated during several consecutive manufacturing procedures.

Although VSR has many benefits that make it a better option than thermal treatment in most cases, there are still some disadvantages and challenges that make manufacturers reluctant to use it. Perhaps the most significant disadvantage is the lack of theoretical knowledge behind the process. The mechanism of Vibratory Stress Relief is still uncertain and its application for the most part depends on experimental results. This makes it extremely difficult to determine the amount of relieved stress and the duration of the process. This lack of information may result in incomplete stress relief or fatigue, as manufacturers are obliged to rely on trial and error. In terms of other disadvantages of VSR, its limited effectiveness for extrusions, cold-worked parts and alloys high in copper as well as the difficulty of application on open-space structures can be pointed out.

In conclusion, VSR is an efficient method for relieving residual stresses. It has many advantages such as maintaining the mechanical properties and physical features of components, its versatility and easy access to the equipment. This method is also cheaper than thermal treatment, which can guarantee a better return on investment (ROI) for manufacturers. Even though lack of knowledge of the mechanism and reliability of this method can be a discouraging factor for many, VSR has proved itself in experiments and case studies. Its proven effectiveness, in addition to its many benefits, makes VSR a suitable alternative for thermal stress relief and ageing for many applications.

In conclusion, VSR is an efficient method for relieving residual stresses. It has many advantages such as maintaining the mechanical properties and physical features of components, its versatility and easy access to the equipment. This method is also cheaper than thermal treatment, which can guarantee a better return on investment (ROI) for manufacturers. Even though lack of knowledge of the mechanism and reliability of this method can be a discouraging factor for many, VSR has proved itself in experiments and case studies. Its proven effectiveness, in addition to its many benefits, makes VSR a suitable alternative for thermal stress relief and ageing for many applications.