Introducing the company, Chris Burkitt, the Production Manager at Sherwood says: “We’re based in the West Midlands and have been supplying stainless steel and aluminium products to a wide range of sectors for over 30 years. We supply coil, blanks, sheet and aluminium extrusion to customers, supporting the construction, automotive and EV sectors.”

What are some of your biggest challenges?

“One is the increasing complexity and precision—especially in EV projects. There’s also constant pressure on lead times and the need to maintain traceability. This kind of work is opening opportunities, especially EV production and light-weighting to improve efficiency and maintain aesthetic quality. The charging infrastructure and the construction industry are areas we continue to grow and thrive in.”

How did you first come across Quickgrind?

“Through industry contacts. We’d been looking for a tooling partner who could support our machining operations with both off-the-shelf and bespoke solutions. We wanted to improve tool life, surface finishes, and reduce cycle times—particularly in aluminium.”

Was there something that stood out?

“Their messaging around innovation and ‘Infinite Possibilities’ caught our attention, but it was the combination of technical expertise and flexibility that convinced us to get in touch and visit Quickgrind in Tewkesbury. It was an excellent experience. Seeing their manufacturing facility, meeting the team, and learning about their development process gave us real confidence in both their product quality and their service culture.”

How has the collaboration evolved?

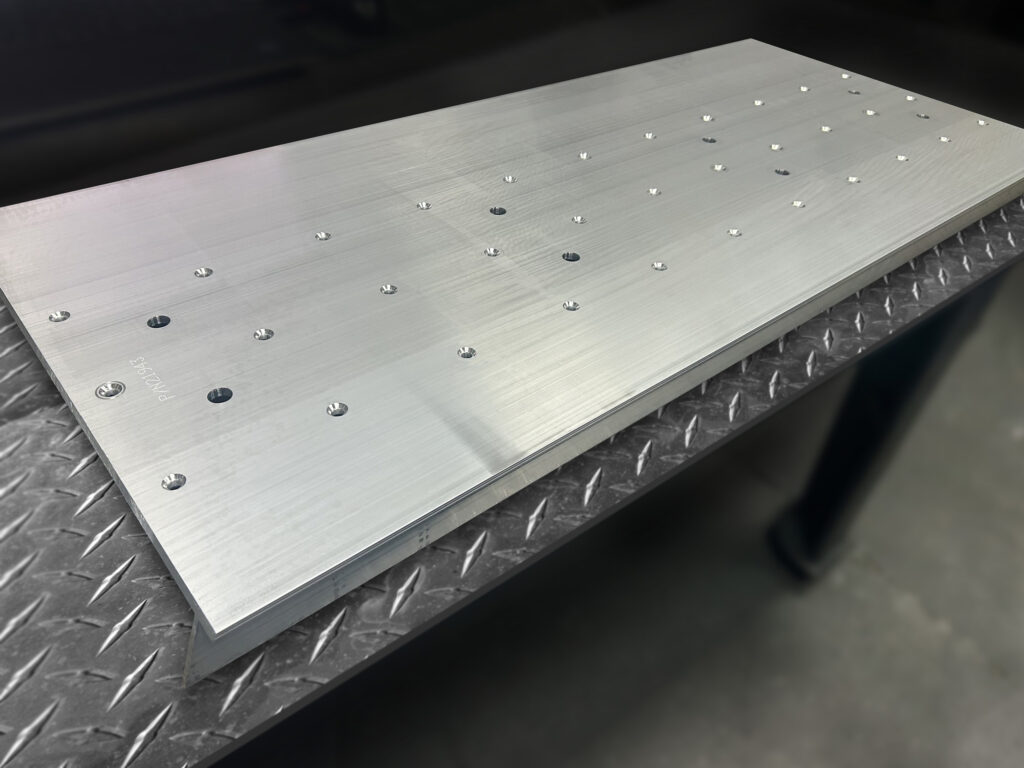

“Very smoothly. There’s been constant dialogue, prompt delivery of samples, and quick turnaround on any adjustments needed. We started as a customer, but now we’re working together on development projects—trialing new tool geometries and coatings. We’ve used a mix of Quickgrind tooling across our operations, recently switching all of our drills over to their solid carbide drills. We have also relied on the Alligator range of end mills as these are designed for aluminium and other non-ferrous applications.”

Some of your team have attended cutting tool seminars at Quickgrind—what was the feedback?

“Very positive. The sessions improved our understanding of tool selection, correct feeds and speeds, and how to maximise tool life. It’s already making a difference on the shop floor. The Quickgrind team is professional, approachable, and collaborative. They listen to feedback and genuinely act on it. They are more than a supplier—they’re a strategic partner who helps us find better ways of doing things.”

How would you rate their innovation?

“Outstanding. They have a knack for translating a production challenge into a practical, high-performing tooling solution. Alongside this, Quickgrind also supplies us with special tools, developed specifically for our requirements, which is a real advantage and this ability to customise tooling quickly, their technical support, and their willingness to work alongside us rather than just sell to us is what sets them apart.”

Have you seen tangible results from tools?

“Yes—longer tool life, faster machining cycles, and better finishes. In one case, a specially designed multi-tool reduced our machining time by 65%, which has had a huge impact on productivity. That means fewer secondary operations, lower overall costs, and faster delivery to our customers. There have also been times when we needed urgent support for a new project and they turned around tooling faster than we thought possible, going above and beyond for the customer.”

How important is an innovative tooling partner?

“It’s vital. Automotive moves quickly, and if your tooling partner can’t keep up, you will fall behind. Going forward, Quickgrind will develop tooling for us to be more efficient, explore new materials, and meet the evolving needs of the market. They are a partner that will listen, adapt, and deliver. The ethos of ‘Infinite Possibilities’ has certainly come through for us. They have helped us unlock machining approaches we had not considered before.”