With over 50 years in the industry, Rydal Precision Engineering Ltd has recently purchased a Matsuura MX-520, its first 5-axis machining centre. To complement the purchase of the 5-axis machine, the Swanley subcontract business has also invested in the Lang Makro Grip zero-point workholding solution.

As a subcontractor that offers precision machining, EDM and grinding as well as punch press tooling design and manufacture, the Kent company invested in the 5-axis machine and Lang workholding solution to improve both productivity and reduce set-ups and cycle times.

Looking at the Lang solution, Paul Rhodes from Rydal Precision Engineering says: “We went for the Lang workholding solution as we needed something modular that gives us a clamping force where we could hit a job hard. We machine hard materials, so we need to have that grip, but we also need to have access to the component. With the system being modular, we can build up the part and bring it to a level where we can get all the aspects of the machining.”

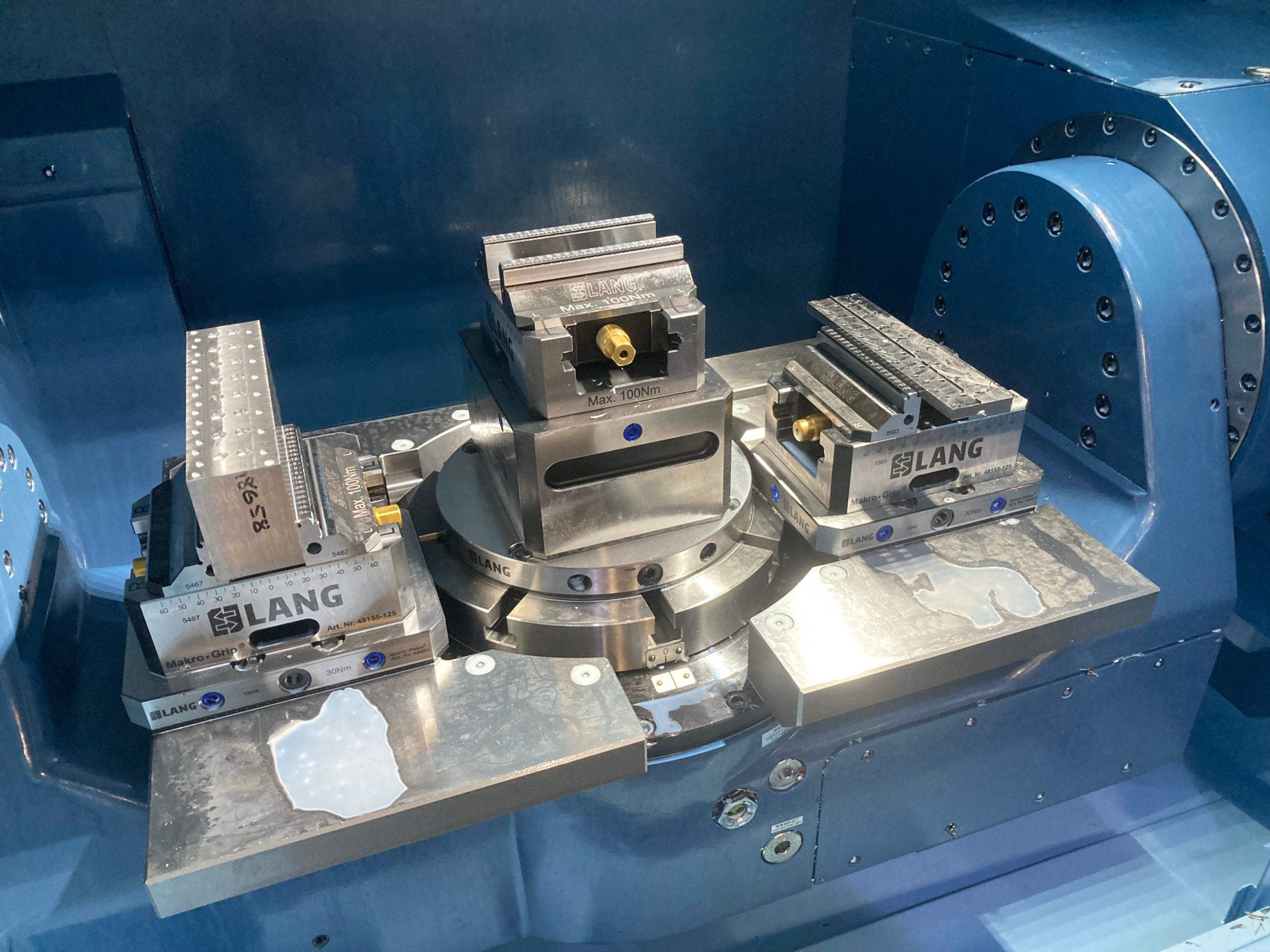

The set-up on the Matsuura MX-520 5-axis machining centre incorporates three Lang vices in the work envelope. Alluding to this, Paul says: “We can go up to 5 vices in the work area but because we have the side of the table, we can bring two vices to the front of the work envelope and two more at the back. We don’t have a pallet machine, but this effectively gets us as close as we can get to it, as we have modular fixtures that we can change in and out. We can also have different setups. At the moment, we have two jobs on the machine, and we could have up to 5 depending on how the workholding fits.”

Discussing the difficult materials that the company machines, and how the Lang vices support this endeavour, Paul says: “The clamping forces are immense. It holds onto the part and the 100Nm of torque equates to tonnes of clamping force. This means that once we have hold of the component, we can hit it hard, remove a lot of material and not worry about the part coming out – even though we are only gripping on 3mm of material. That means that we do not have to buy excess material to sit inside a vice that ends up as waste.”

Rydal pre-stamps the components with teeth indentations that are created by the Lang system. This has a marker to show where the zero point is on each component. “This allows us to align each component. For example, one component we are machining at the moment has undergone the rough machining cycle and we can now send that part for stress relieving and when it comes back to us, we will locate it in exactly the same position for finish machining by using the pre-indentations created by the Lang system.”

With the subcontracting company investing in Lang workholding solutions for the first time, Paul says: “I looked in the market for a solution and Lang was the name that came to mind, and of course, it was capable of doing the job. They offer a complete solution that is exactly what we needed and we can use it across our other processes as well. Now, we can effectively move the existing product and the Lang vice into other machining centres and onto grinding machines and even onto our wire EDM machines – we can use it anywhere within our machine shop.”

Referring to the repeatability, accuracy and ease-of-use, Paul adds: “It’s a very accurate system, it relocates within microns and it’s very simple to use. To use it, it is just a case of undoing one Allen key and lifting the part out.”