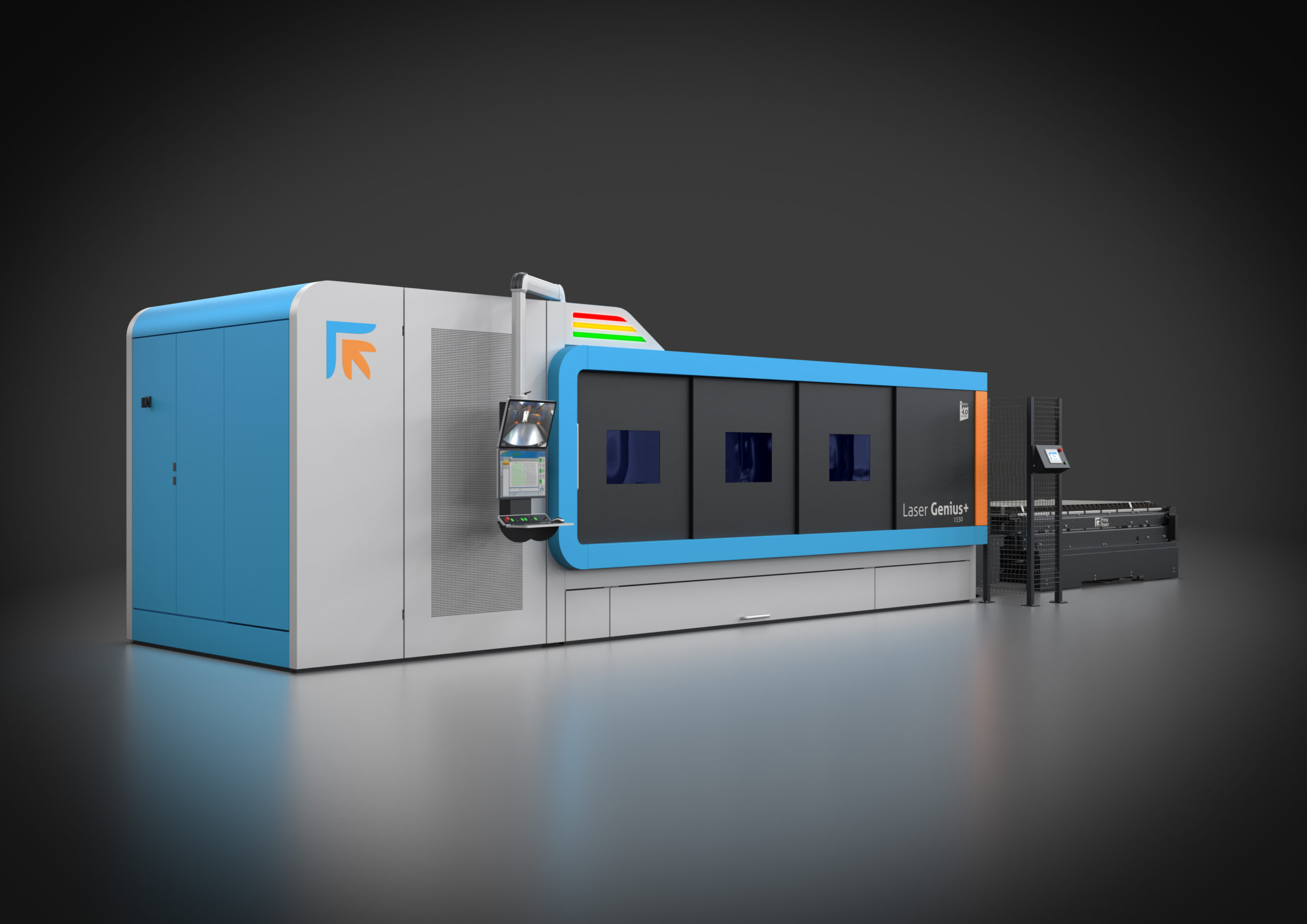

The Prima Power range of 2D machines has been expanded with the new Laser Genius+ that has been developed to improve performance, efficiency, quality, ease of use, automation and intelligence.

With a trajectory speed of 180m/min, the Laser Genius+ is designed to make the most of its available laser power. The Laser Genius+ machine family includes 1530, 2040 and 2060 size models and can be equipped with a wide range of fiber laser power options up to 15kW. The new laser head has been designed to manage the heat required to melt thick materials whilst staying cool and clean. This is achieved with sensors that actively control the cutting process in real-time, hermetically isolated optics, simplified mechanics, and a high-efficiency fume extraction system.

Its footprint integrates all of the services into one dedicated module separated from the working area to make the machine an extremely compact, plug & play system with very quick installation times. The Laser Genius+ has the largest working area when compared to alternative machines. The X, Y and Z-axis strokes are 3,150 by 1,600 by 150mm for the 1530 model and 4,320 x 2,200 x 150mm for the 2040.

The laser head boasts adaptive optics for the automatic management of the focal position and diameter and a fast, reactive and precise measurement of the stand-off from a single focusing lens suited to all production requirements. This is complemented with a Side Impact Protection Systems (SIPS), Optical Precision Control (OPC) and a protective glass drawer for easy inspection.

A new 24” high-definition dual monitor console and simplified user interface have also been designed for the Laser Genius+. The information panel on the machine also displays data such as details of processed materials and energy consumption in real time – highly useful for operators and production managers.