When using X-ray CT for non-destructive quality control of larger components like aluminium castings, the challenge is to shorten inspection cycle times. One prerequisite for achieving this is high X-ray intensity or flux. In Nikon’s range of X-ray CT systems, a rotating target can already triple the flux for a given focal spot size and the flux can be further increased by motorised FID.

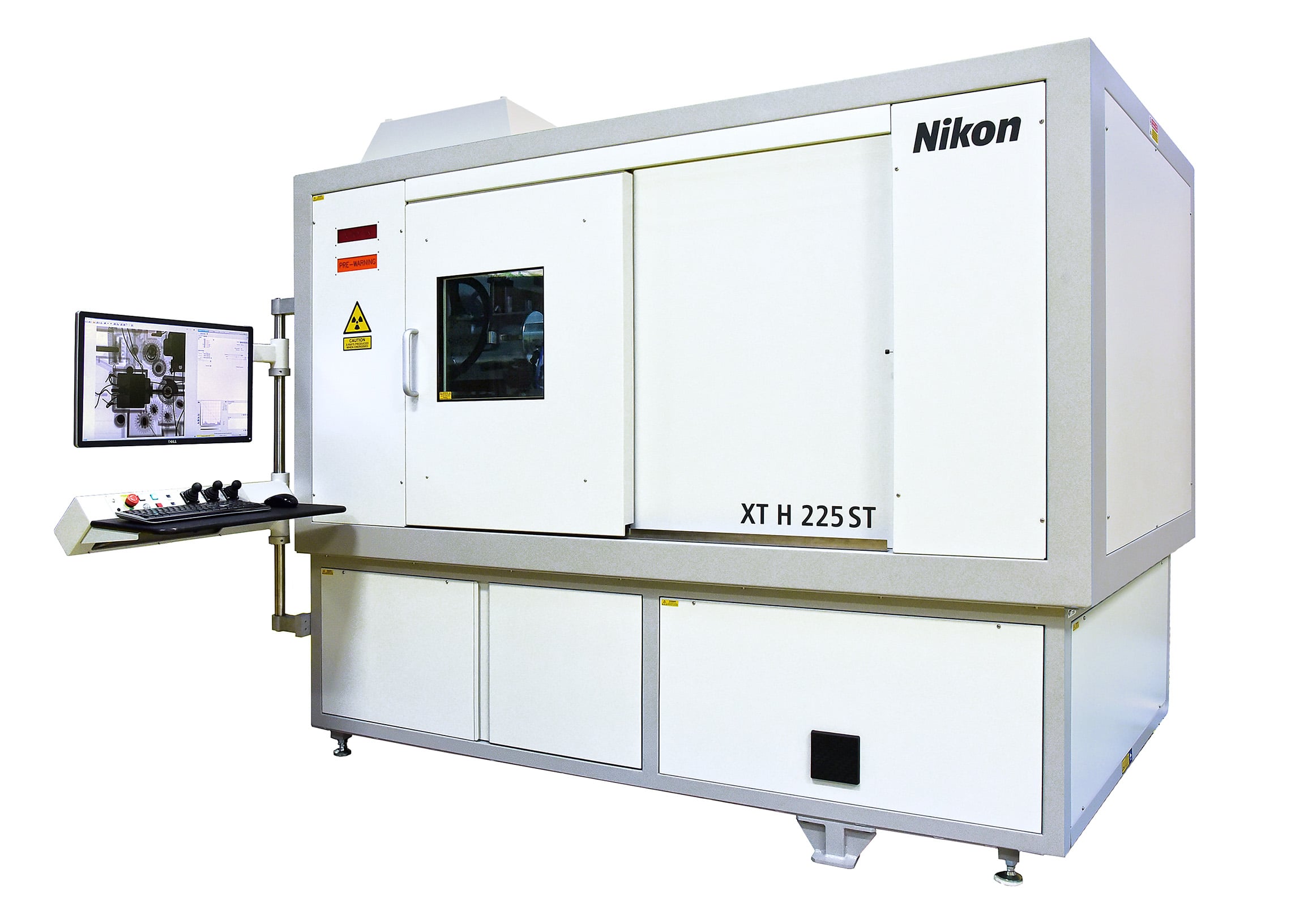

With the release of a new offset CT reconstruction algorithm in the latest version of the Inspect-X software, not only can larger components be scanned but it can also be performed at higher geometric magnification. The Offset CT module is available on all Nikon Metrology X-ray CT systems from 180kV through to 450kV.

With this combination of the latest Rotating Target 2.0, adjustable FID and Offset CT, times are reduced and better resolution is achieved. Offset.CT is a scanning method that allows small or large components to be inspected fully while only part of the sample is within the field of view (FOV). The component is placed such that only just over half of the object lies within the X-ray cone beam, allowing a much wider FOV and reconstruction volume. Adjustable FID is a standard feature in Nikon Metrology 225kV XT H systems and Large Envelope CT systems up to 450kV. It serves to improve the signal-to-noise (SNR) ratio and the image quality of digital radiographs and 3D voxel data, in addition to allowing increased scanning speed.