🎧Motorsport subby takes pole position

2025 is already proving to be a memorable, standout year for leading precision motorsport subcontract specialist, Northants Precision Ltd. In addition to acquiring two more DN Solutions’ Lynx 2100 lathes from Mills CNC, the company has successfully completed its relocation to larger premises, increased its headcount, and secured new machining contracts.

Led by owner and Managing Director Daniel Green, Northants Precision continually aims for excellence.

The machines, an 8” chuck, long-bed Lynx 2100LMB with driven tooling, and a 6” chuck, 2-axis Lynx 2100A, were installed at the company’s new 3500sq/ft. manufacturing facility in Kislingbury, Northampton, in January and June 2025.

Both machines are equipped with powerful, high-torque spindles, servo-driven turrets, rigid roller-type LM guideways, and hydraulic tailstocks. The Lynx 2100A offers a maximum turning diameter of 350mm and a turning length of 330mm with its 15kW/6000rpm spindle and 12-station turret, while the long-bed Lynx 2100LMB provides a 300mm turning diameter and 510mm turning length, featuring a 15kW/4500rpm spindle, 12/24-station turret, and 6000rpm driven tooling capabilities.

The new machines are positioned adjacent to four previously acquired Lynx lathes, a Lynx 2100B (2022), a Lynx 2100MB (2021), a Lynx 2100LMB (2021) and a 10-year-old Lynx 220LSY. Together, these six FANUC controlled machines, three with driven tooling capabilities, provide Northants Precision with a formidable in-house turning and milling resource. All feature the advanced FANUC iPlus control with 15” touchscreen iHMI, making them ideal for meeting the accuracy needs and fast turnaround demands of motorsport customers.

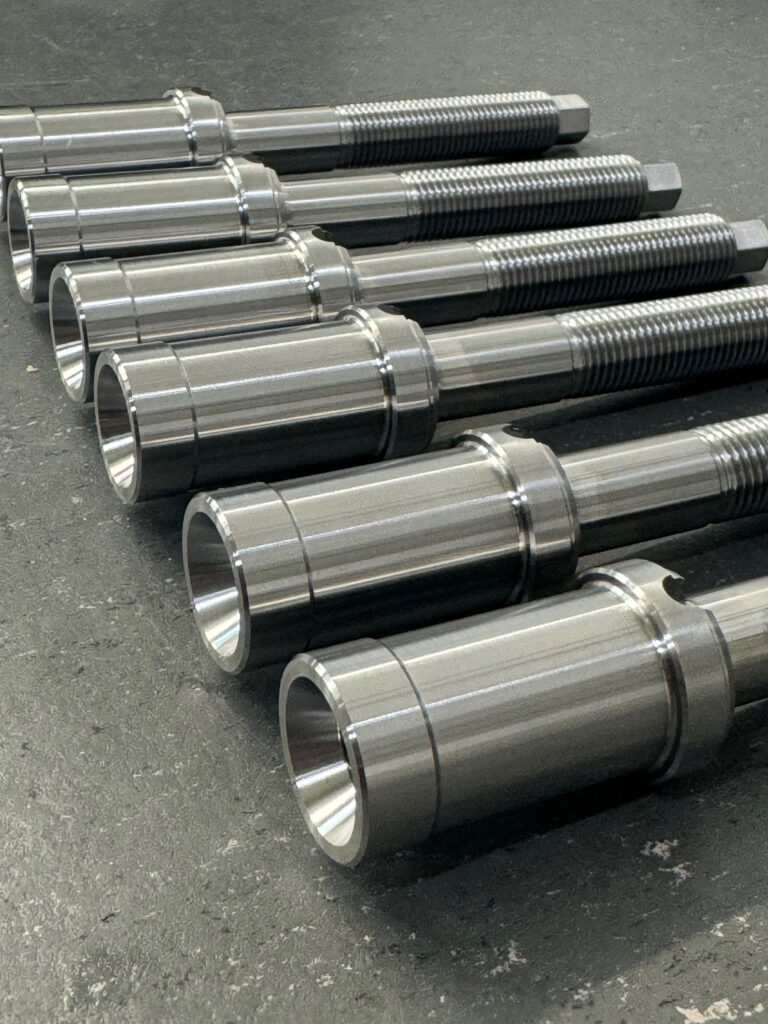

Since installation, the new Lynx lathes have been machining a range of small, complex, and high-precision engine, chassis, sub-frame, and gearbox components for F1, WEC (World Endurance Championships), WRC (World Rally Championship), and supercar customers.

Parts machined on the Lynx lathes are typically washers, nuts, bolts, and top hats. They are characterised by tolerances of +/-5 microns on specific features, a flatness of 0.01mm, and strict surface finish requirements. These parts are machined in small-to-medium batches from solid bar stock. The primary materials processed include heat-treated stainless steels (13-8PH and MP35N), titanium 6242/6246 alloys, and aluminium.

Part cycle times range from just a couple of minutes up to 10 minutes, and to ensure accuracy, concentricity, and flatness, parts are securely held using Hainbuch collet chucks. Daniel Green: “Machining and supplying hundreds, sometimes thousands, of identical high-precision and performance-critical parts from hard, difficult-to-machine materials to exacting quality standards is commonplace for us. But to achieve this consistently requires reliable, high-performance machines and proven CAD/CAM, machining, and inspection processes. We have invested significant resources to ensure we have all of these in place.”

Northants Precision regularly monitors its performance to identify potential production bottlenecks and address them before they become problematic. The company’s success in securing small part machining contracts from new and existing customers, including recent contracts won directly with F1 racing teams, prompted capacity reviews at the end of 2024 and during Spring 2025, ultimately leading to orders for two new machines.

Daniel Green continues: “F1, and motorsport in general, is demanding and challenging. You always have to be ‘on top of your game’ and constantly meet customers’ quality and lead time requirements from day one. Failing to do so quickly tarnishes your reputation and means your days as a supplier in the sector are numbered. Our positive experiences with DN Solutions Lynx 2100 lathes and Mills CNC’s pre and after-sales services meant that, on both occasions, we made Mills our ‘first port of call’, ultimately investing in the new Lynx 2100A and Lynx 2100LMB.”

A typical machined part is an engine housing washer component made from 10mm diameter pre-cut titanium bar stock supplied in 42” lengths. These parts are machined to completion in medium-sized batches (600-off) using two of Northants Precision’s Lynx 2100 lathes positioned opposite one another to create a flexible manufacturing cell, operated by one member of staff.

Front-end ID and OD turning are performed on a Lynx 2100 (two-axis) lathe, where a bar puller ensures a reliable process and continuous production. After the initial operations, which take about 2 minutes per part, the semi-finished parts are individually loaded into the Lynx 2100LM for back-end processing. This involves machining an angled groove or chamfer on each part, which takes approximately 30 seconds.

Says Daniel Green: “We strive for excellence across the board. Everything we do, from our in-house CAD/CAM, machining and inspection to any outsourced processes – is integrated and carefully controlled.”