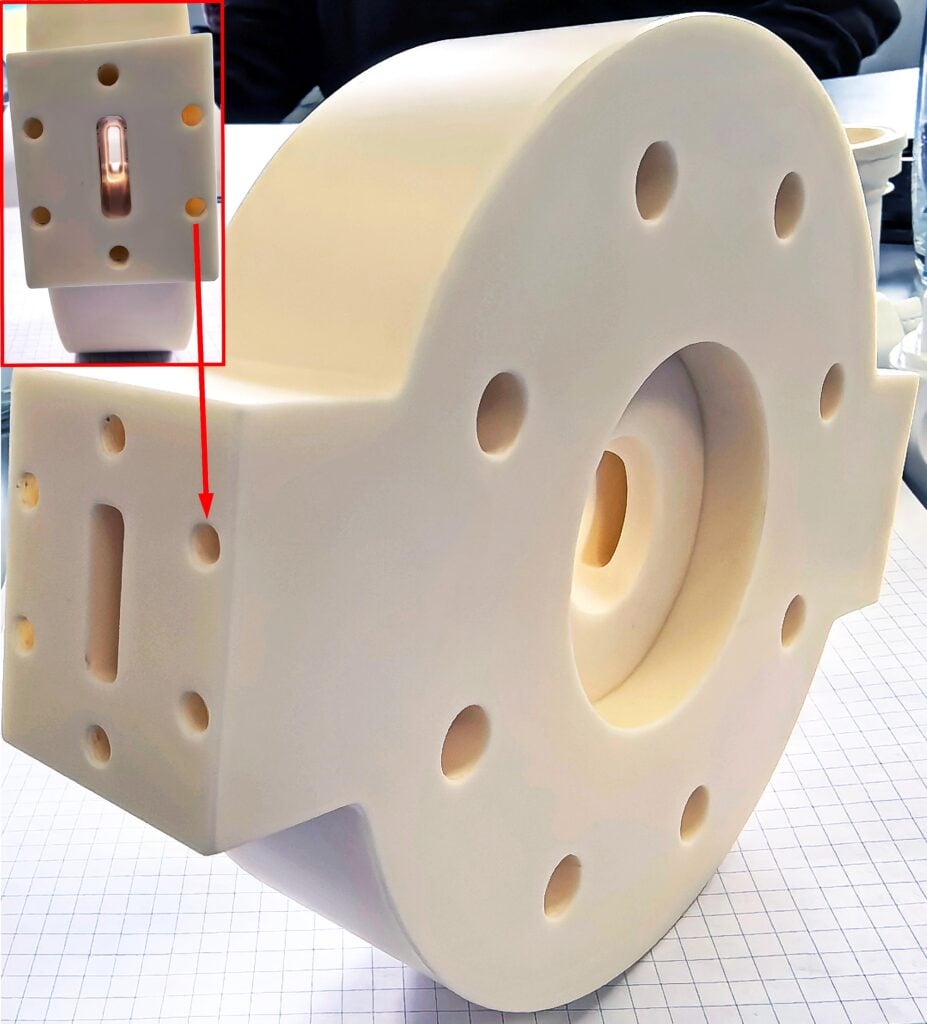

Industrial ceramics are essential in many high-performance applications due to their exceptional hardness, thermal stability and chemical resistance. However, their extreme hardness – up to 1800HV makes machining after sintering nearly impossible except by grinding, which is a relatively expensive process and limits geometric complexity of the component being produced.

BCE Special Ceramics GmbH in Mannheim has now successfully broken this barrier using a high-speed (42,000 rpm) Roeders RXP 501 DS trunnion-type, 5-axis machining centre. It is achieving micron precision by milling as well as grinding, reducing cost and allowing more sophisticated machined features. Hurco Europe, the UK agent for the German machine manufacturer, describes the technological advance.

Founded in 1986, BCE specialises in ceramic components such as aluminium oxide, zirconia, and composite ceramics like ATZ (alumina toughened zirconia) and ZTA (zirconia toughened alumina). The company serves industries ranging from medical to aerospace, producing custom parts from single prototypes to medium-size series.

Each application is developed in collaboration with the customer’s R&D team. The process begins by selecting the optimal ceramic material, sometimes modified with additives for enhanced properties like conductivity.

Production in Mannheim begins with pressing a ceramic powder mixed with a small amount of organic binder into a green compact. This fragile but machinable part is strengthened through cold isostatic pressing at around 2,000 bar. It is still relatively soft and must be oversized by about 20% to compensate for shrinkage during sintering.

Subsequent firing at a temperature between 1,300°C and 2,000°C removes the binder and fuses the ceramic particles into a dense, durable structure with only 0.5% porosity. After sintering, these ceramics possess outstanding hardness, chemical resistance and temperature tolerance down to absolute zero. However, their hardness presents a machining challenge.

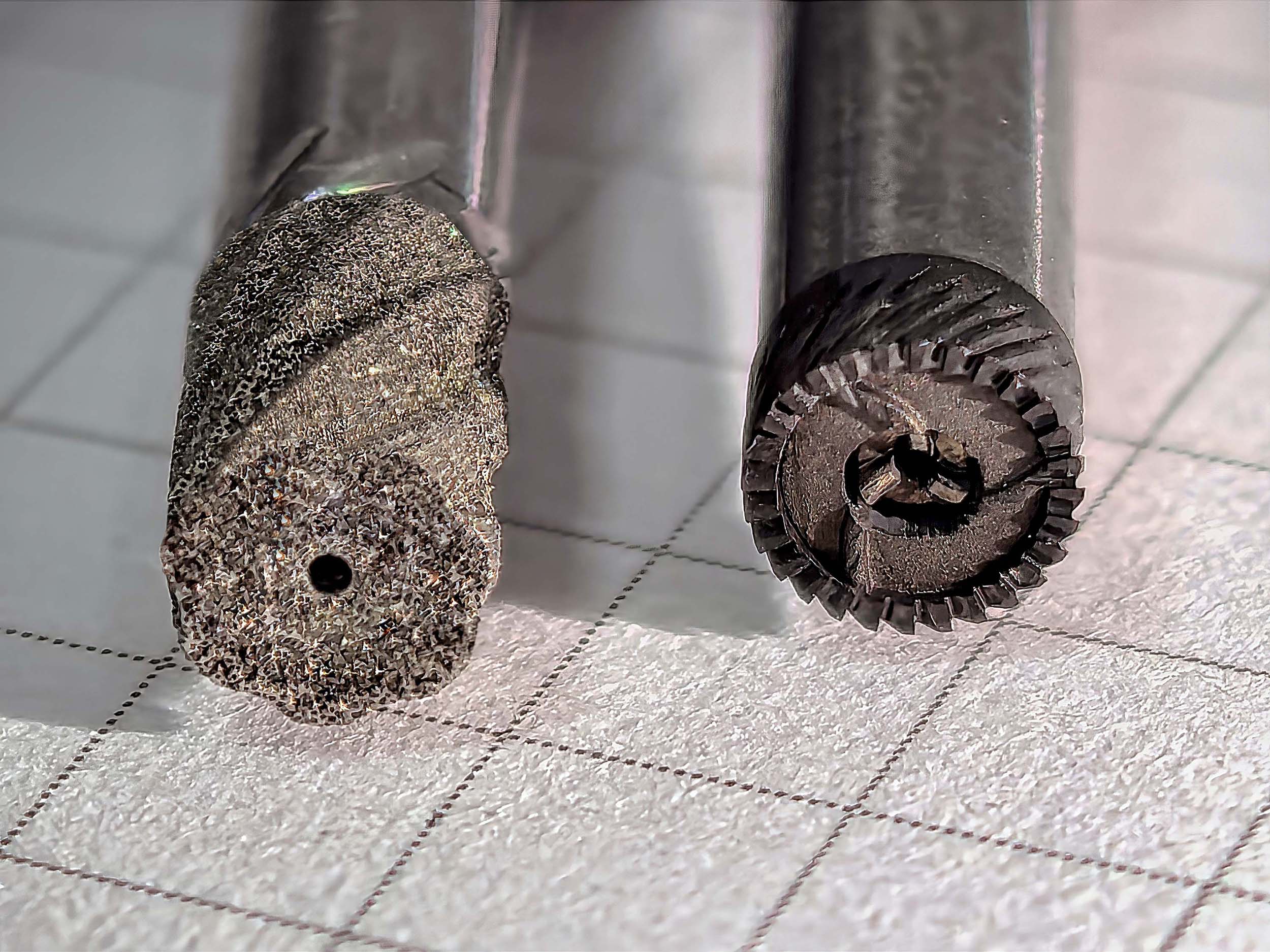

Historically, grinding was the primary method for machining sintered ceramics, especially when precision was needed. In BCE’s applications, for simpler 2D and 2.5D geometries, predefined grinding cycles using mounted points exchanged from the tool magazine are frequently used. Milling cutters and drills are utilised for more intricate 3D geometries and surfaces.

Dr Torsten Prescher, application engineer at BCE said, “When we researched the market for machining centre platforms able to mill as well as grind our ceramic materials, Roeders stood out for its control systems and machine components, which allow unmatched contouring accuracy. The roundness of our machined holes is to within one micron.”

Roeders machining centres use direct drives, robust linear guideways and protective sealing to avoid ingress of abrasive ceramic dust. Both manual and CAD/CAM programming is supported, allowing operators to choose the most efficient workflow. The machine is supplied with built-in grinding cycles, a dressing spindle and acoustic sensors for process monitoring. Through-tool cooling of the cutting zone using an emulsion at pressures up to 80 bar ensures tool longevity and machining accuracy.

BCE partnered with high-performance tool manufacturer Zecha to address the challenges of milling ultra-hard ceramics. It supplied custom polycrystalline diamond (PCD) and diamond-coated carbide tools designed for high-wear, high-precision requirements.

Fabian Henning, a mechanical engineer at the Mannheim factory found the Roeders system intuitive to operate. For simpler 2D and 2.5D components, he often programs NC grinding sequences directly at the machine. The Roeders control not only uses its own grinding cycles, but also retrieves parameters from an internal machining database to speed programming. For more complex geometries, Mr Henning uses a seat of VISI CAM to create milling cycles.

BCE’s Managing Director Dr Torsten Weiss concluded: “Machining systems we looked at from other potential suppliers were capable of milling green parts, but they proved inadequate for high-precision 5-axis machining of fired ceramics.”

“The existence of approximately 50 Roeders machines already in use around the world for various ceramic machining tasks also provided a convincing reference.”

“The decision to invest in Roeders has been pivotal to our business. We can now machine sintered ceramics into geometries previously unheard of.”