🎧Microloc transforms Scottish engineering operations

Situated near Alva in Central Scotland, Qualtek Engineering serves everything from small customers to large international corporations with CNC machining services. Alongside its main manufacturing activities, Qualtek operates Bespoke Engineering, a specialist automotive division concentrating on restoration, classic cars, performance vehicles, and motorcycles. It is here that Microloc clamping technology is used.

The nature of Qualtek’s work demands versatility that traditional workholding solutions struggle to provide. Ewan Montgomery, who oversees operations, explains: “It’s a very individual workshop with diverse needs. We specialise in restoration, classic cars, performance cars, and motorcycles, which means we’re constantly dealing with different projects needing different tooling approaches.”

This diversity extends to tooling manufacture. “A good example is working on a classic car cylinder head with modern machinery,” Montgomery notes. “Buying old-fashioned face cutters commercially is hard to get and hugely expensive for standards that we don’t really need. Manufacturing our tooling became a cost-effective solution.”

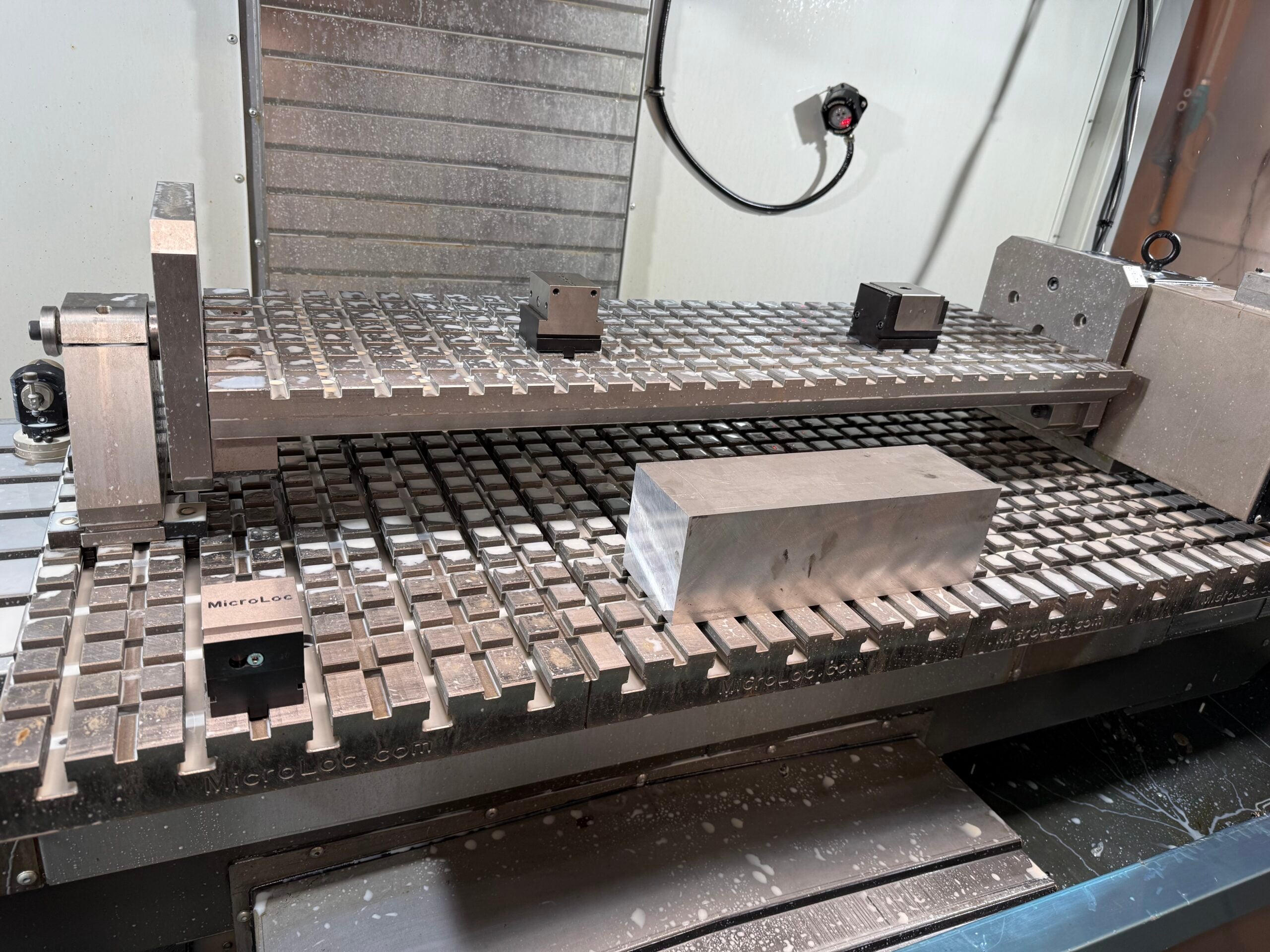

To accommodate substantial automotive components, Qualtek invested in a HAAS VF4SS machining centre. “The machine size is really to accommodate the size of materials that we’re working with—engine blocks, cylinder heads, etc. You need a certain size of footprint; otherwise, if they don’t fit, you can’t work,” Montgomery explains.

Discovery of the Microloc Solution

The introduction of Microloc workholding proved transformational. “Microloc was completely the solution that we didn’t know we were looking for,” Montgomery admits. “Very soon after I bought the machine, I’m buying a Microloc system, and it’s really one of the best things we’ve ever done.”

Technical Advantages

The Microloc system achieves exceptional accuracy through its integer location methodology, where components are clamped against fixed jaws, providing precise location in X, Y, and Z axes. The system maintains repeatability accuracy of ±25 microns, achieved through case-hardened jaws ground to ±10 microns relative to tenon keys.

“The system is designed for machinists, and it’s designed to minimise setup time and provide micron-level accuracy,” Montgomery explains. “There’s nothing else out there that delivers this kind of modular setup that Microloc provides.”

The precision aspect is crucial for automotive restoration work. “The accuracy, as we understand from manufacturing our own tooling, just a few microns out is enough to scrap a part,” Montgomery emphasises.

One significant advantage is eliminating traditional setup procedures. “Traditional clamp vices have to be set up, have to be clocked in if you’ve got multiple operations,” Montgomery notes. “Things can move because it’s friction clamping, not keyed clamping, and you’ve got lots of variables, including temperature, user, and everything else that can go wrong.”

Modular Flexibility

The modular design allows clamping elements to be rotated through 90 or 180 degrees, enabling four-edge clamping configurations. Individual clamping modules deliver exceptional holding power. “The clamping force on these is unbelievable. I think we’re approaching a ton of pressure,” Montgomery reports. “You can place them anywhere on your table within 3mm of movement.”

“It doesn’t matter if it’s a metre-long part or if it’s a 100mm long part, you’ll find a clamping place that will accommodate that width or length,” Montgomery explains. “You can have as many of these Microloc clamps as you wish on the table. You can have nested systems for repetitive work.”

System Configuration and Fourth Axis Integration

The Microloc baseplate mounts using bore tenon adaptors that locate into precision 16mm bores. The baseplate features precisely spaced, conical zero-point locations that accept tenon keys of various workholding elements.

Integration of fourth-axis capability opened up new possibilities for complex automotive components requiring specific angles. “A lot of the machining originally was done off-centre,” Montgomery explains. “This particular manifold is at 45 degrees and using the fourth axis and the HAAS VF4SS machine accuracy, we can get that exactly to 45 degrees straight away.”

Customisation and Service Support

Rather than a standardised package, Microloc provided a tailored solution. “It’s a custom solution to suit a customer’s needs. It’s not a defined package. It can be made larger, smaller, wider, whatever, just depending on customer demand,” Montgomery notes.

Service support extended beyond supplying the system. “Microloc provided tenons to fit our vices to make them quick release as well, so that we don’t really have any setup time now,” Montgomery explains. “When we have no clocking-in required, just simply mount them on X or Y-axis, and if that’s what you need, it will be instantaneous. It’s a five-minute job, and you’re ready to go.”

Operational Efficiency and Quality Improvements

Time savings achieved through the Microloc system have directly impacted operational efficiency. “The old way of doing it would be to set up a manual table, an indexing table, and you would be there for a very long time trying to get that right. Obviously, time is money,” Montgomery reflects.

Perhaps most revealing has been the insight into historical manufacturing standards. “The conventional machining on older engines from around the world was not accurate, to say the least,” Montgomery observes. “When you are doing things like cylinder boring with a machine that can measure so accurately, you understand that the tolerances that things were made to were quite poor. We can make them better now than they were when they came out of the factory.”

For Qualtek Engineering, adopting Microloc workholding has represented a fundamental shift in operational capability. The combination of precision, flexibility, and efficiency has enabled the company to tackle increasingly complex projects whilst reducing setup times and improving accuracy. In an industry where precision measured in microns can determine success or failure, the Microloc system has provided the foundation for sustained growth and enhanced capabilities in both general manufacturing and specialist automotive restoration work.