The new HG350-G new precision gear grinding centre from PTG Holroyd is the first from PTG Holroyd and believed to be the first in the UK – to use Siemens’ new Sinumerik ONE future-proof CNC, the successor to the automation specialist’s 840D CNC.

PTG Holroyd has committed over £1.6m to develop it’s brand new gear grinding centre, a machine that has been designed to give the company an edge in the horizontal form grinding of high-quality gears. “We plan to build two HG350-G machines to begin with,” comments Regional Sales Director, Mark Curran. “One will remain on-site in Rochdale for R&D purposes. The other has been purchased by a long-standing PTG Holroyd customer.”

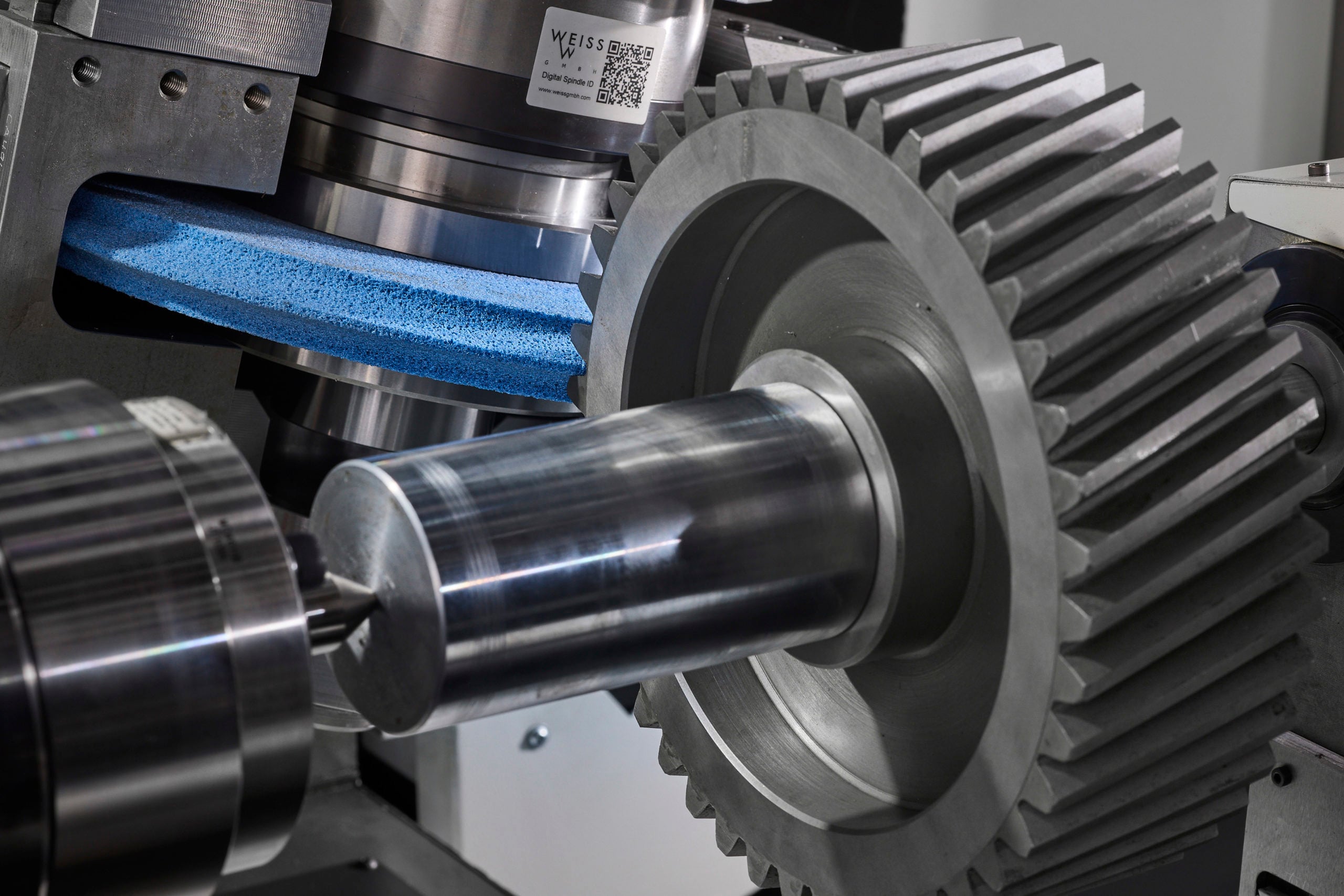

In designing the HG350-G, PTG Holroyd’s goal was to offer customers much more than a new generation machine for the one-off and batch grinding of high-accuracy precision spur and helical gears, as well as worms and screws of up to 350mm in diameter.

Replacing PTG Holroyd’s established GTG2 model, the HG350-G features the high power required for deep grinding operations. A specially developed extended machine bed allows screws and worm shafts of up to one metre in length to be accommodated. Dedicated software compensates for helical twist, and full topological capability comes as standard. Embracing the Sinumerik ONE CNC’s Profinet capabilities, IO-Link communication technology will be offered with all new HG350-G machines.