When an engineering firm’s mantra is ‘no compromise on quality,’ it simply can’t afford inaccuracies. Addison Precision delivers bespoke precision components and assemblies to the aerospace, military transport and mining industries. Supplying advanced applications to clients across Europe for almost four decades, it has more than 100 full-time engineers and harbours ambitions for further growth. And that’s one of the reasons it turned to ZOLLER UK.

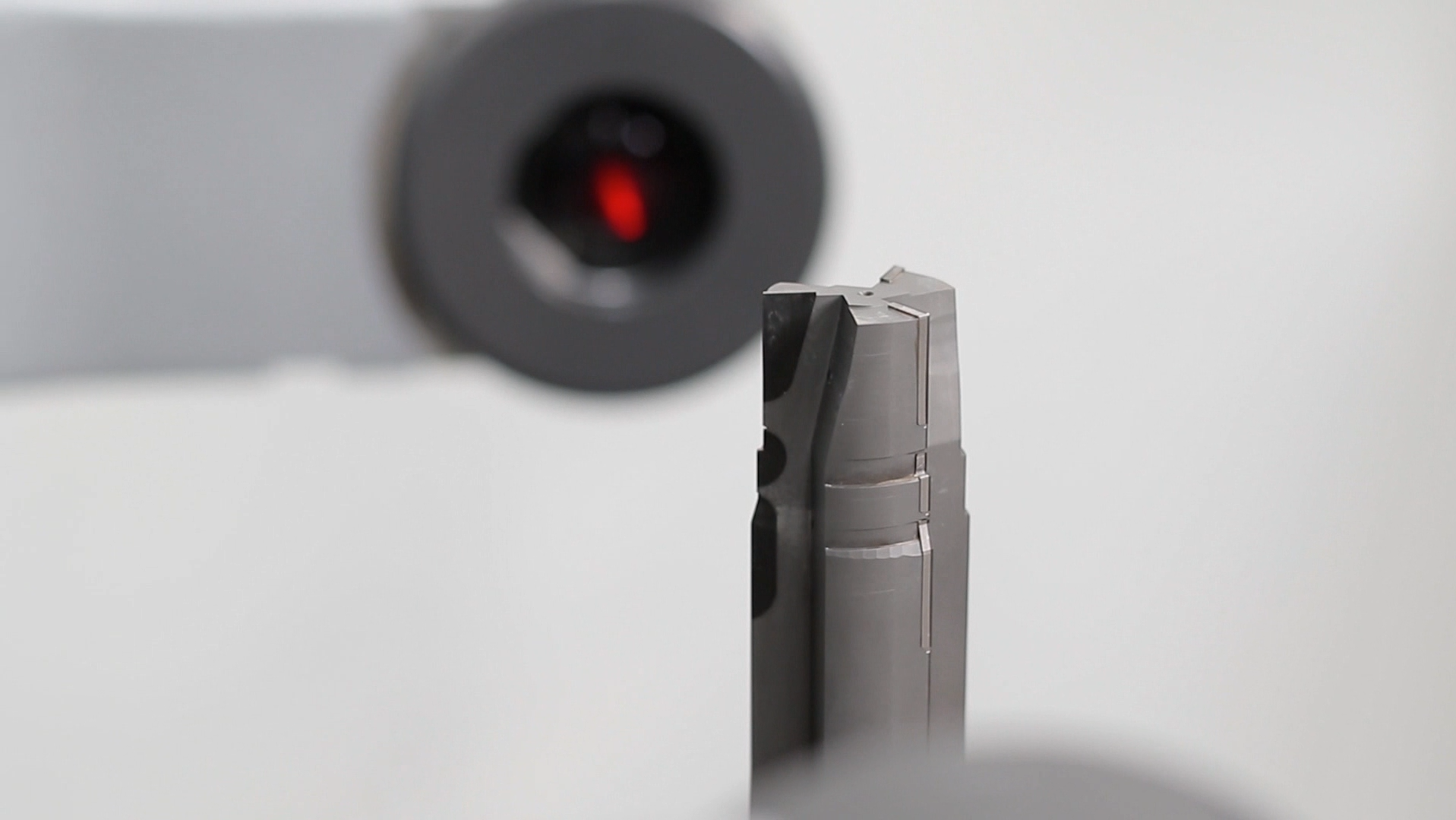

Don Hopper, Special Projects Manager at Blackpool-based Addison, explained: “Our customers expect parts to a schedule, right first time, every time. We’re measuring tolerances to microns. We started research into getting some pre-setting equipment so that we’d have the ability to measure the tools built into an assembly before putting them anywhere near a machine tool. The idea behind that is to check that everything is correct – we use a lot of PCD-type tools which, if you touch with metal, can be damaged, so a contactless measuring system is absolutely brilliant.”

Dedicated to tool pre-setting and inspection equipment, ZOLLER UK has best-in-class, intuitive and ergonomic technology to ensure tools are of the right quality to create accurate parts before machining. By introducing increased efficiency to their production cycles, businesses are guaranteed a rapid return on investment as well as a significant boost in reliability.

Addison opted for the ZOLLER Venturion 450; a system equipped for the shop floor. Mr Hopper said: “I would recommend the ZOLLER. Our experience has been flawless. All of our guys like the interface, they’re just amazed at what it’s capable of doing. The beauty of the machine is its power-clamping system. It’s interchangeable – you don’t need to mess around changing back-end adapters. The power-clamping unit drops in, you put whichever back end it is you want to check the tooling and away you go.”

“This has enabled us to have more accurate detail of what we’ve set. We’re measuring tool runout, which is very important on reamers, boring bars and things like that.”

Being safe in the knowledge that nothing has been left to chance with the Venturion 450 is proving invaluable for Addison. Mr Hopper said: “We’ve come up with a system where we measure the tools with the ZOLLER, we save that to a file on the network and that’s then downloaded directly into the machine control. So, there’s no manual operator input and that’s a big step forward.”

“It’s reassuring that you’ve checked everything because before with the lasers you could only check tool length and the biggest diameter without a lot of additional programming. With the ZOLLER, we put together a tool card which has details of the tool assembly in its entirety, so we’re not only measuring the cutting tool and the important surfaces on it – we can also check the holder it is in and ensure the correct diameter. That means it’s not likely to collide and it has the right amount of tool reach to clear all the obstacles on the machine while it’s in operation.”

According to Mr Hopper, the quality of customer service offered by ZOLLER UK from its base in Foston, near Derby, has also been second to none. He said: “ZOLLER came in, installed the equipment, moved it into position, made sure everything was correct, calibrated it and then we got a comprehensive two-day training package. It was very, very useful and very comprehensive.”

“When we’ve asked for help they’ve always been there – it’s just been great. We just pick the phone up or send an email and they get straight back to us. There’s never been an issue.”

“It was very fortunate that the owner of our business just happened to be on-site at the time during the ZOLLER demonstration. He looked over our shoulders at what was going on and was so impressed with it that he phoned up and negotiated the deal to purchase the equipment. Ultimately, the plan is to grow our business, so by adding additional machines there may come a time when we need to purchase more ZOLLER equipment, but at this moment in time, it copes with everything that we can throw at it.”