Edging ever closer to an environmentally sustainable future, the automotive industry is in the throws of transition. Whether it be electric vehicles (EV), hybrids or the potential of hydrogen vehicles, the pace of change has rapidly picked up over the last few years.

The seismic changes in the automotive sector demand new types of components such as electric motor housings, gear housings, new examples of covers and all accessories related to E-mobility. There will be increased demand for re-tooling, new tooling and processes to produce these components in a high-volume environment that will remain key to the industry. Cycle times and savings from financial and time constraints will always be a concern, so it’s important to get things right from the very beginning.

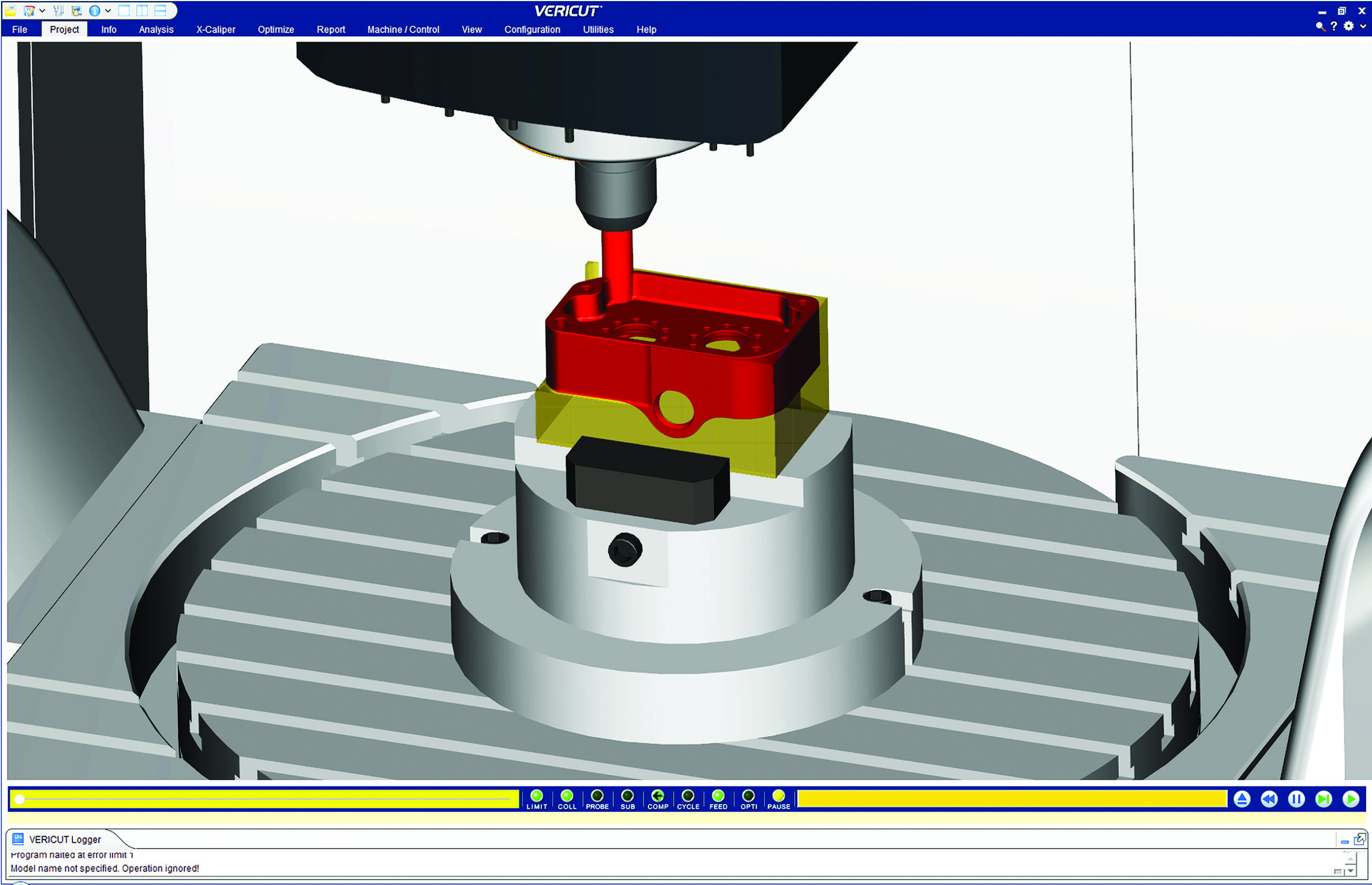

Every step in the engineering, design, CAM programming and machining process should be inspected, verified and optimised and it is here that simulation software ensures programmes are error-free. Adding to this, optimisation ensures the whole process is operating as efficiently as possible to save time and money. The VERICUT independent CNC machine tool simulation from CGTech, enables users to link all the machining operations end-to-end to evaluate and improve the manufacturing process.

Manufacturers typically have very high volumes, so the cost per unit and cost control is extremely important. The focus is on planning production efficiently from the start. Considering the production environment – the machines, their automation, the required floor space, raw materials and invested capital –the initial information required for accurate process planning can be significant. This is where VERICUT can analyse the process before machining takes place or before any material is cut, reducing the prove-out time.

The major challenges when proving-out automotive parts for the first time can range from scrapped parts, broken tools and holders to fixture or spindle repair or replacement. Ultimately, this can result in machine downtime, schedule disruption, insufficient capacity and lost contracts. VERICUT can resolve these issues and eliminate factors that are going to cost downtime, money and safety on the shopfloor.

VERICUT becomes part of the process once the NC code has been created. The engineer, who is offline from the machine can perform a virtual prove-out and identify potential issues in the NC program. VERICUT verifies the post-processed G-Code instead of the CL data. This is the same G-Code that runs within the NC system of the machine, enabling the software to carry out a comprehensive machine simulation. Any errors will be highlighted in the VERICUT logger, which when clicked on will link directly back to the line of NC code where the error occurred. Simultaneously, rather than sitting idle, the machine can be producing parts, thus removing the wait time from the machining process. Valuable machine time is therefore not wasted and machinists can be confident that the program will deliver without collisions or disruption.

Simulation and verification create an error-free, safe environment to deliver the parts as intended. However, there are opportunities to make components more quickly – issues include inefficient programming and sub-optimal feed rates caused by the CAM system’s inability to adjust cutting feed rates for varying cutting conditions. VERICUT Force addresses the issues. The goal for efficient CNC machining is to achieve a constant chip thickness. Maintaining a tool’s ideal chip thickness through an operation ensures that the tool is being used to its full potential, which in turn reduces machining cycles, increases tool life, and makes programs safer. VERICUT Force is a software module that uses a physics-based optimisation method to determine the maximum reliable feed rate for any given cutting condition based on four factors: force on the cutter, spindle power, maximum chip thickness and maximum allowable feed rate. It calculates feed rates by analysing tool geometry and parameters, material properties of the stock and cutting tool, detailed cutting tool edge geometry, and cut-by-cut contact conditions.