Gearboxes used in electric vehicles are not only designed for high speed and torque – but they are also very compact. This is also true for innovative applications such as e-bikes. These high power electrically driven gearboxes inspire design engineers to come up with more creative solutions. With gear manufacturing technology manufactured by Kapp Niles, the Engineering Technology Group (ETG) offers innovations for producing EV and e-bike gearboxes.

In many cases, gearboxes comprise small components with interfering contours that pose production challenges. For hard finishing of the gear teeth, the process-related potential goes hand in hand with high production costs. The most economical option is generating grinding. However, not all machines are suitable for the compact components. Here, the experts at ETG outline the demands and solutions.

Transmission manufacturing challenges include the high power density and the compact installation space in which the entire powertrain must be accommodated. At the same time, new applications are opening up new sales opportunities, such as e-bikes.

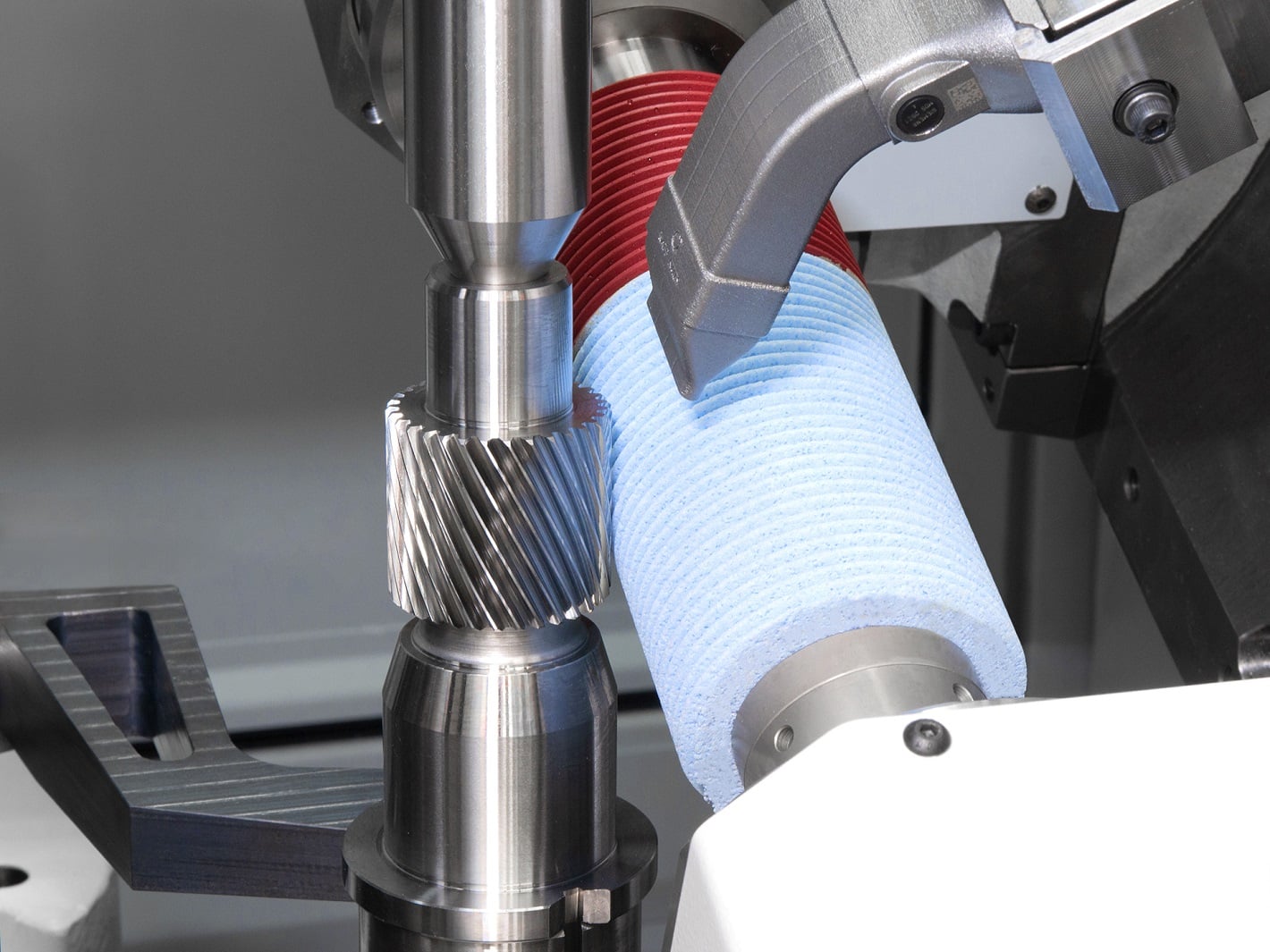

This benefits the manufacturers and their suppliers – gearbox manufacturers among them. However, be it two or four wheels, the drive technology is sophisticated. The focus is on the required flank load capacities and the noise behaviour of the gear teeth due to the boundary conditions imposed by the electric drive motor, an almost constant high torque over the speed range of 0 to 18,000rpm. However, new challenges go beyond machined parts and also directly affect the manufacturing process. Due to the compact design, an increasing number of components with interfering contours emerge in the gearbox design. Large tools with standard dimensions of the worm grinding wheel quickly and literally meet their limits.

Identify and overcome boundaries

Up to now, the finishing of gears with interfering contours has been accomplished by discontinuous profile grinding or honing. Compared to continuous generating grinding, both processes feature different disadvantages in terms of productivity, economic efficiency or quality consistency. The problem is that common grinding worms measuring 300mm diameter are too large to handle components with interfering contours.

At the same time, smaller tools require higher cutting speeds. However, previous machine concepts were not designed for the high dynamic requirements regarding tool and workpiece driving. New types of high-speed spindles in combination with a dynamic direct drive of the workpiece axis offer a solution. This enables manufacturers to exploit the advantages provided by generating grinding – a process that features shorter machining times, lower tool costs and quality consistency.

The right machines

Through ETG, Kapp Niles offers two machine types, both equipped with high-efficiency drives for tools (25,000rpm) and the workpieces (5,000rpm). The KNG350 flex HS has a conventional design featuring one workpiece drive. The machine is available in two versions, one for miniature and small lot sizes. For higher volumes, an automated version is available with an integrated ring loader. Workpieces up to 350mm in diameter can be processed using this machine.

The machine features short set-up times that are possible through the use of intelligent components ergonomics. For large-scale production, it is worth looking at machines pre-set by design. The KX TWIN series with two workpiece drives and a loading and unloading process that is performed in parallel to the actual grinding operation offers further potential for the reduction of non-productive times.