‘If you always do what you’ve always done, you’ll get what you’ve always had’ is a truism that CGTech, the CNC simulation developer of VERICUT has been stating to manufacturers since the 1980s.

Visitors to the MACH stand 218 in Hall 19 will find out from the leader in NC code simulation how the software can take their business to the next level. With VERICUT, CGTech offers a wide range of products and solutions that ensure CNC machine tools run collision-free and manufacturing processes operate more efficiently with increased profit levels.

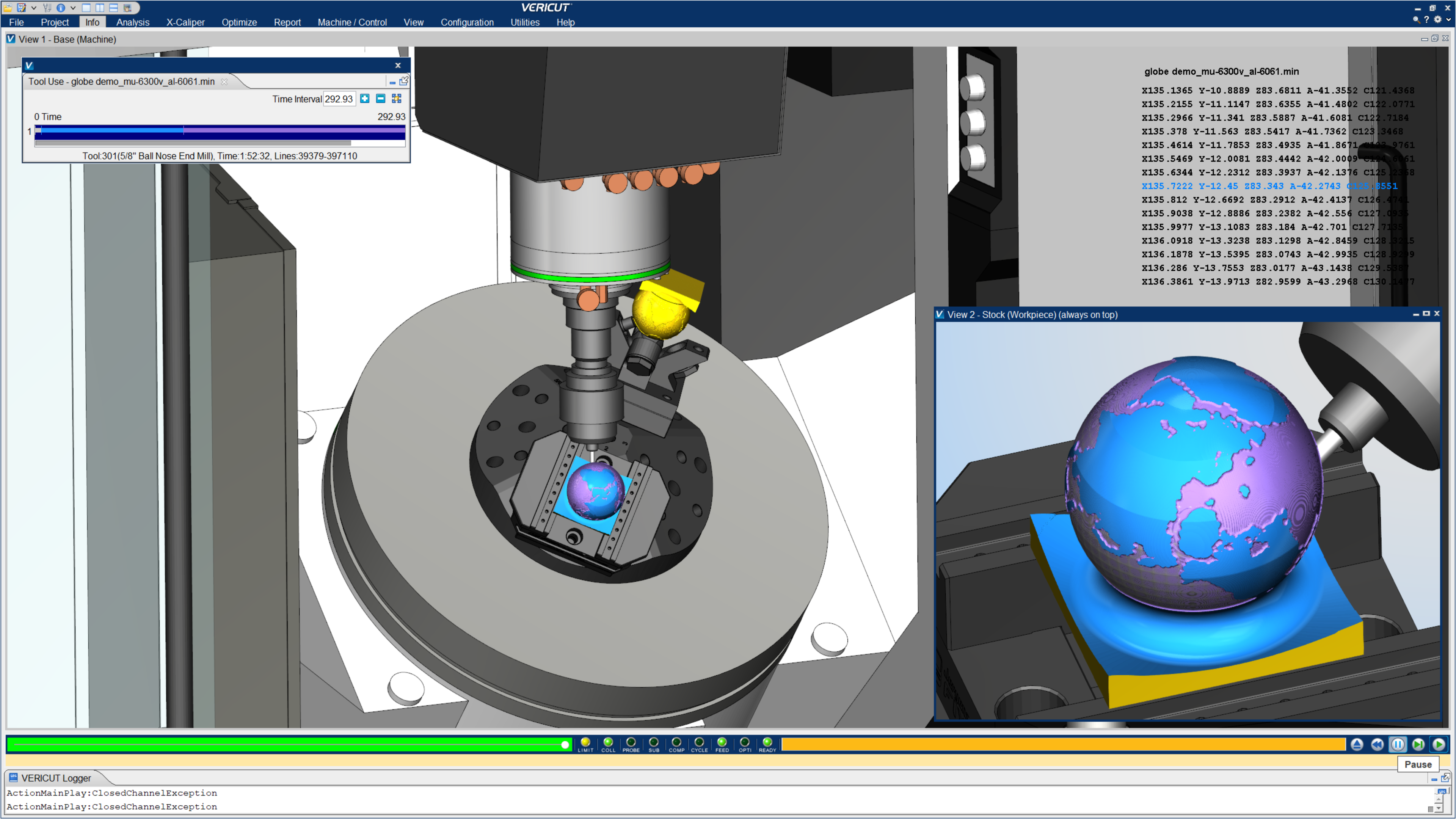

Demonstrations of the latest features in version 9.2, plus an exclusive preview of what’s to come in 9.3 of VERICUT CNC machine simulation and optimisation software will be conducted on the stand by the company’s technical engineers. VERICUT software is an industry-standard for simulating CNC machines to detect errors, potential collisions or areas of inefficiency. It operates independently, but can also be integrated with leading CAM systems.

CGTech will also demonstrate VERICUT’s Force optimisation module at MACH. VERICUT+ Force provides an integrated simulation-optimisation solution that can reduce machining times, improve cutting tool and machine life. New and legacy NC programs can be optimised with Force to run as efficiently and safely as possible. Force is available for milling, turning and mill-turn machines.

Force is a physics-and mathematics-based module designed to optimise feed rates of machine tools. The software uses actual data for cutting tool forces and spindle power readings to calculate maximum chip thickness and feed rate.

Sales Manager, Scott Ravenscroft, explains: “VERICUT covers the visible production elements, such as crashes, scrap, gouges and prove-outs. Force addresses the hidden opportunities. These include inefficient programming and suboptimal feed rates caused by the CAM system’s inability to adjust cutting feed rates for varying cutting conditions.”

Force relies on proven technology to maximise program efficiency and productivity and typically achieves savings of 8 to 15% on aluminium and 15%+ on difficult to cut materials. Return on investment can often be as little as one production component, with the opportunity to analyse cutting conditions, improve tool life, protect CNC machine tools and reduce operational costs.

Gavin Powell adds: “Companies now more than ever are realising the importance of simulation and the digital twin model. We are working closely with our customers and partners around the world to understand their exact needs. We deliver technical and economical solutions through the use of advanced technologies.”