30-taper machining centre produces medical components from tough materials

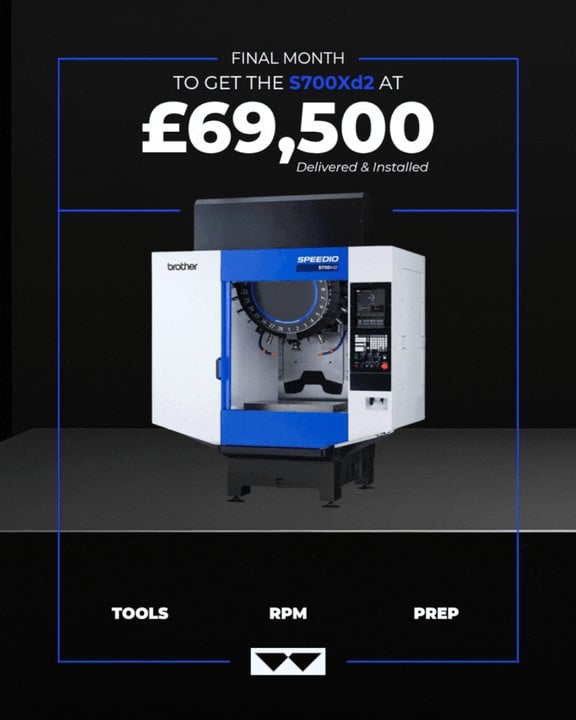

Subcontract machining firm Kirkstall Precision, Leeds, has enhanced its capability to serve the demanding medical sector with the installation of a Brother SPEEDIO M200Xd1-5AX, a Japanese-built, simultaneous 5-axis CNC machining centre supplied by sole UK and Ireland sales and service agent, Whitehouse Machine Tools, Kenilworth.

For the past seven years, the subcontractor has focused almost exclusively on producing components for the medical industry, while also producing surgical instruments and implants for the veterinarian sector. The company is seeing a 15 to 20 percent year-on-year growth rate due to high demand.

The Brother was chosen for its accuracy, repeatability, versatility and compact footprint. Adam Thornton, Kirkstall’s Managing Director said, “Accuracy in the medical sector is a given. Everything has to be completely correct, so we inspect and report all dimensional tolerances. Opting for a top quality machine tool like the Brother was a fairly obvious decision for us.”

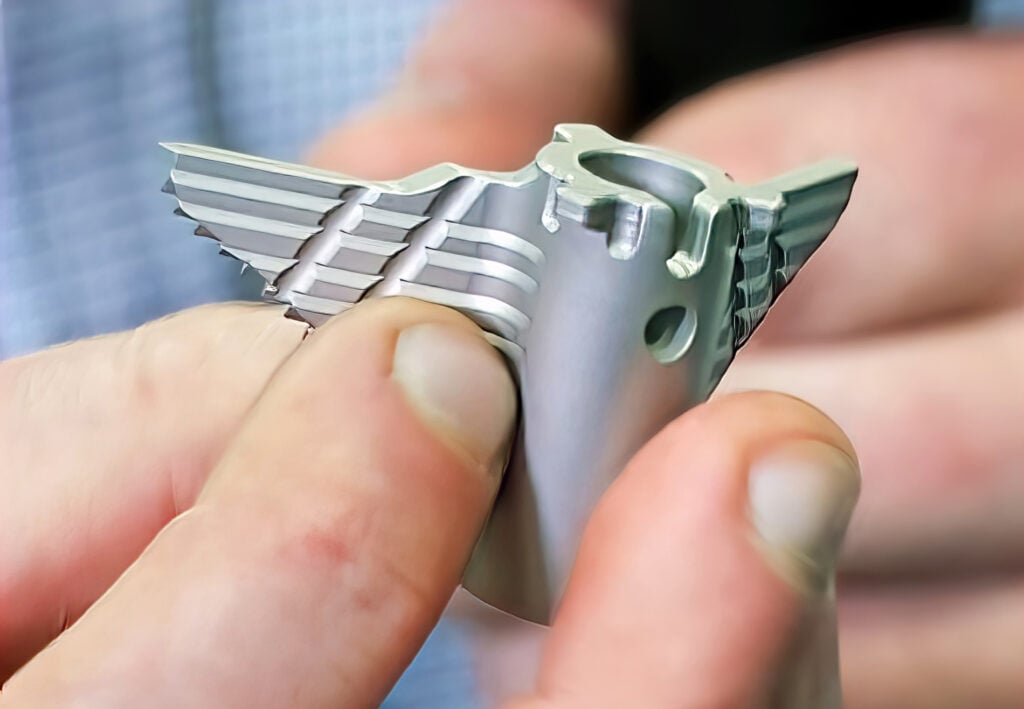

Approved to ISO 13485, a globally recognised quality management system standard for medical devices, Kirkstall produces mainly low-volume orthopaedic components from challenging materials, including stainless steel, hardened stainless, titanium and other tough alloys. The 30-taper SPEEDIO is ideal for machining these materials continually. Additionally, it is able to combine on a single platform 5-axis prismatic machining using the 16,000 rpm spindle with turning using the rotary torque table, which was a further key attraction.

Mr Thornton added, “We’ve used 40-taper 5-axis technology for some time, but the Brother is faster and takes up less space. It’s ideal for the smaller, high-accuracy parts we produce and has delivered typically a 20 percent cycle time reduction compared with our larger production centres.”

One such component, a keel punch for total knee replacement surgery, previously required four separate operations on three machines. The Brother now completes 90% of the features in a single setup, so only a short second operation is needed, reducing cycle time by 30% and improving accuracy. Setup times are faster, the amount of handling has reduced, and most importantly there has been a big improvement in the accuracy of the product, which is machined to within 15 to 20 microns over the entire form.

Another attribute of the SPEEDIO is its exceptional energy efficiency, a key highlight of its design. Compared to traditional 40-taper machining centres, it draws up to 80% less power, which translates into cost savings of several thousands of pounds a year.

Energy saving measures that have been incorporated include power regeneration during deceleration, high efficiency motors driving the spindle and axis motions, an optimised pump for coolant recirculation, LED lighting, low air consumption, and automatic power off when the machine is not being used.

Low power consumption is not just through energy-saving features, but is also inherent in the machine’s design. Fast cutting speeds and rapids, plus an ability to combine milling and turning operations in one setup, lead to reduced cycle times which in turn lowers power consumption.

Mr Thornton concluded, “Whitehouse Machine Tools has been a collaborative partner, very similar to us in terms of values and ambition.

“We plan to add robotic component handling with optical part recognition to the Brother in 12 to 24 months’ time and we feel confident that this supplier will support us with the retrofit.

“We’re forming a medical group in the contract manufacturing sector and are aiming to be world class. Investing in top quality brands like the Brother really adds to this strategy.”