The question that engineers and manufacturers ask when considering their production joining and manufacturing processes is can we do this better, cheaper and more efficiently?

Joining similar, dissimilar or exotic materials directly to each other with a high integrity bond is the holy grail of industrial manufacturing. The benefits of achieving this is to reduce cost, increase quality, efficiency and reliability. All are major considerations for OEM’s competing in the global market place and who need to establish their positions with innovative, quality and cost effective products.

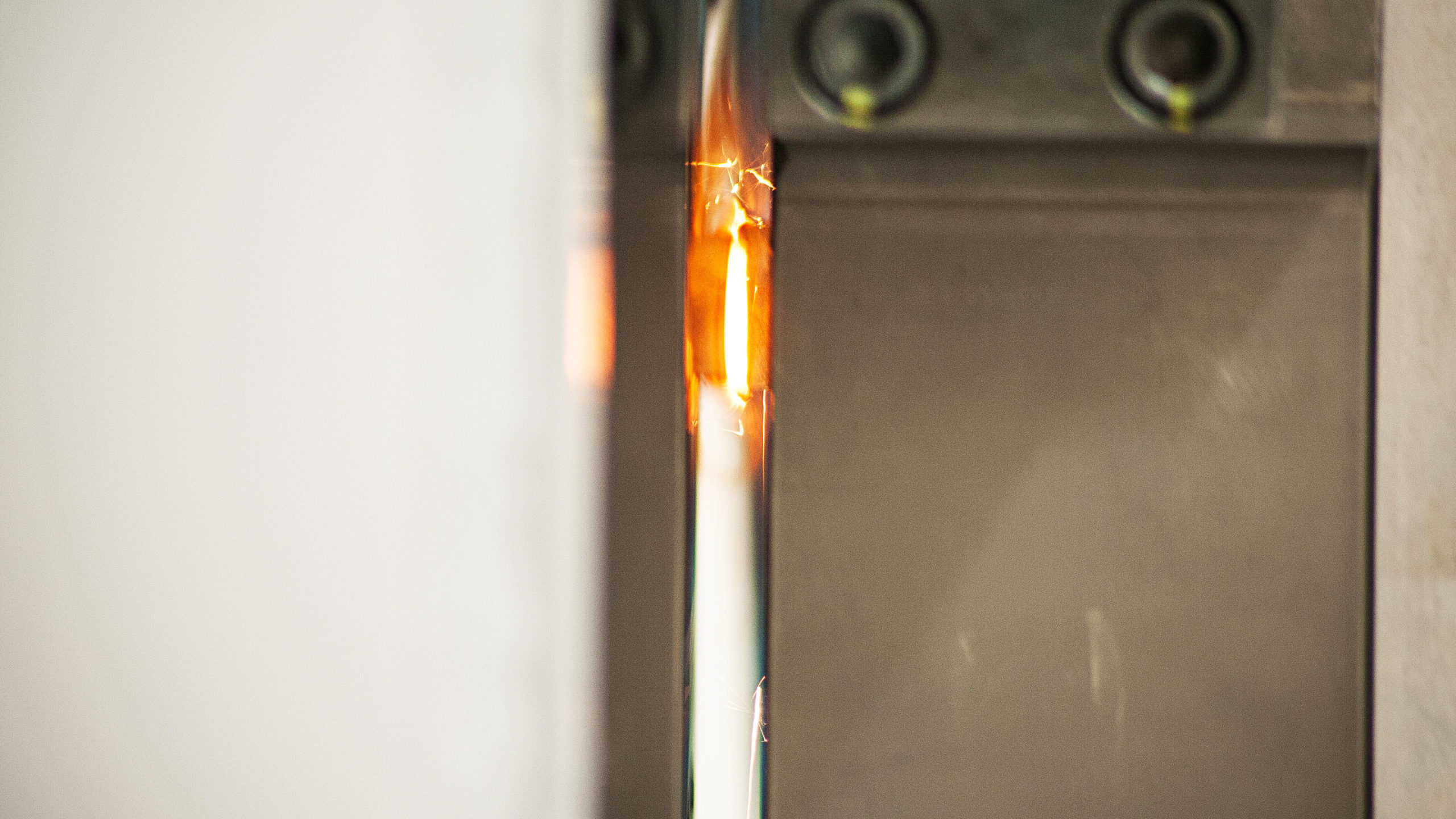

Friction welding processes provide an efficient and sustainable method of achieving high integrity similar and dissimilar material bonds.In this White Paper we will consider the role of friction welding processes in manufacturing today and how it can be used to improve performance, reduce waste and increase product effectiveness.

We will also explain how KUKA/Thompson Advanced Welding Solutions (AWS) can help to access friction welding technology through KUKA Thompson sub-contract services.

For more information click here:-