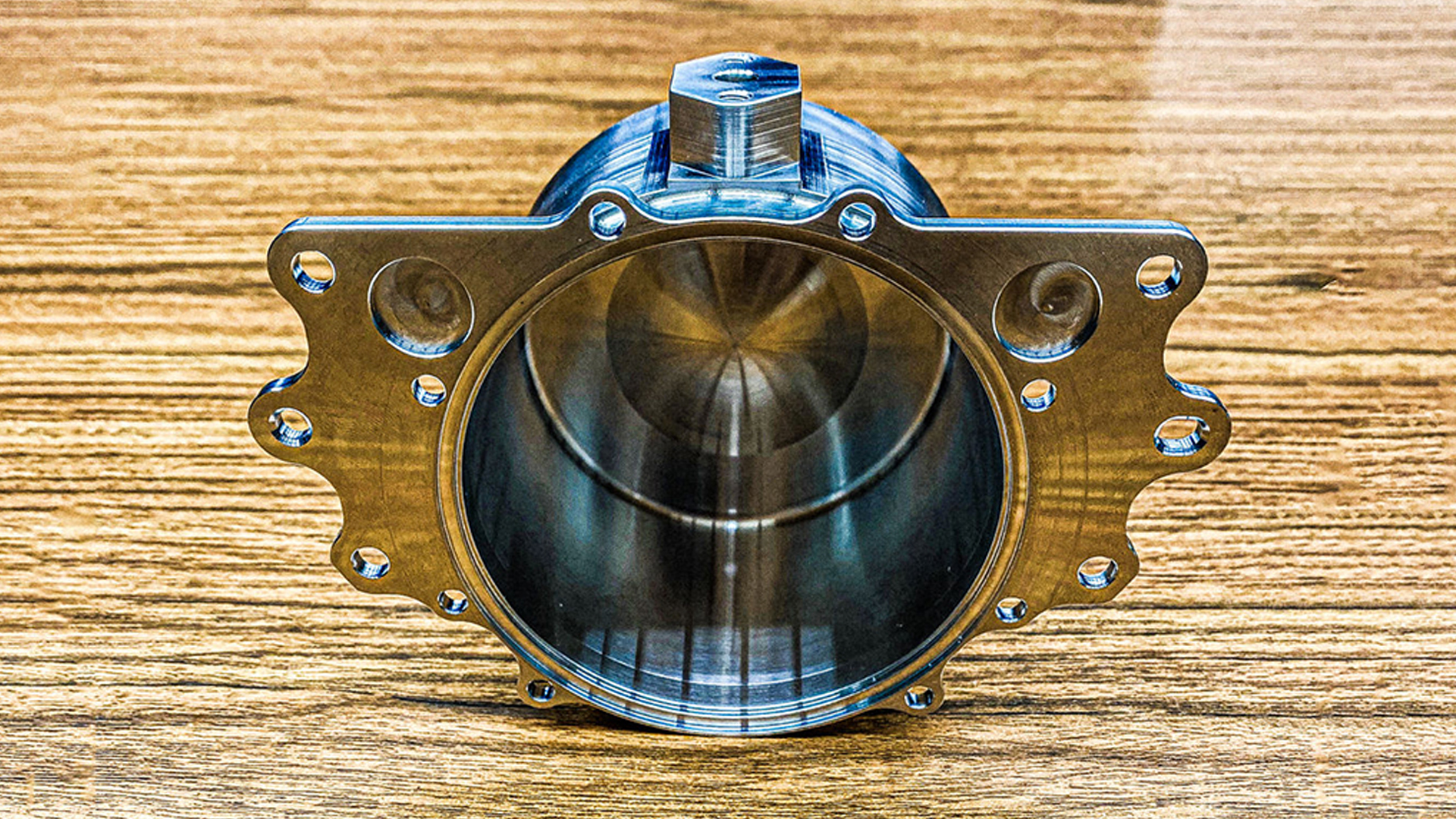

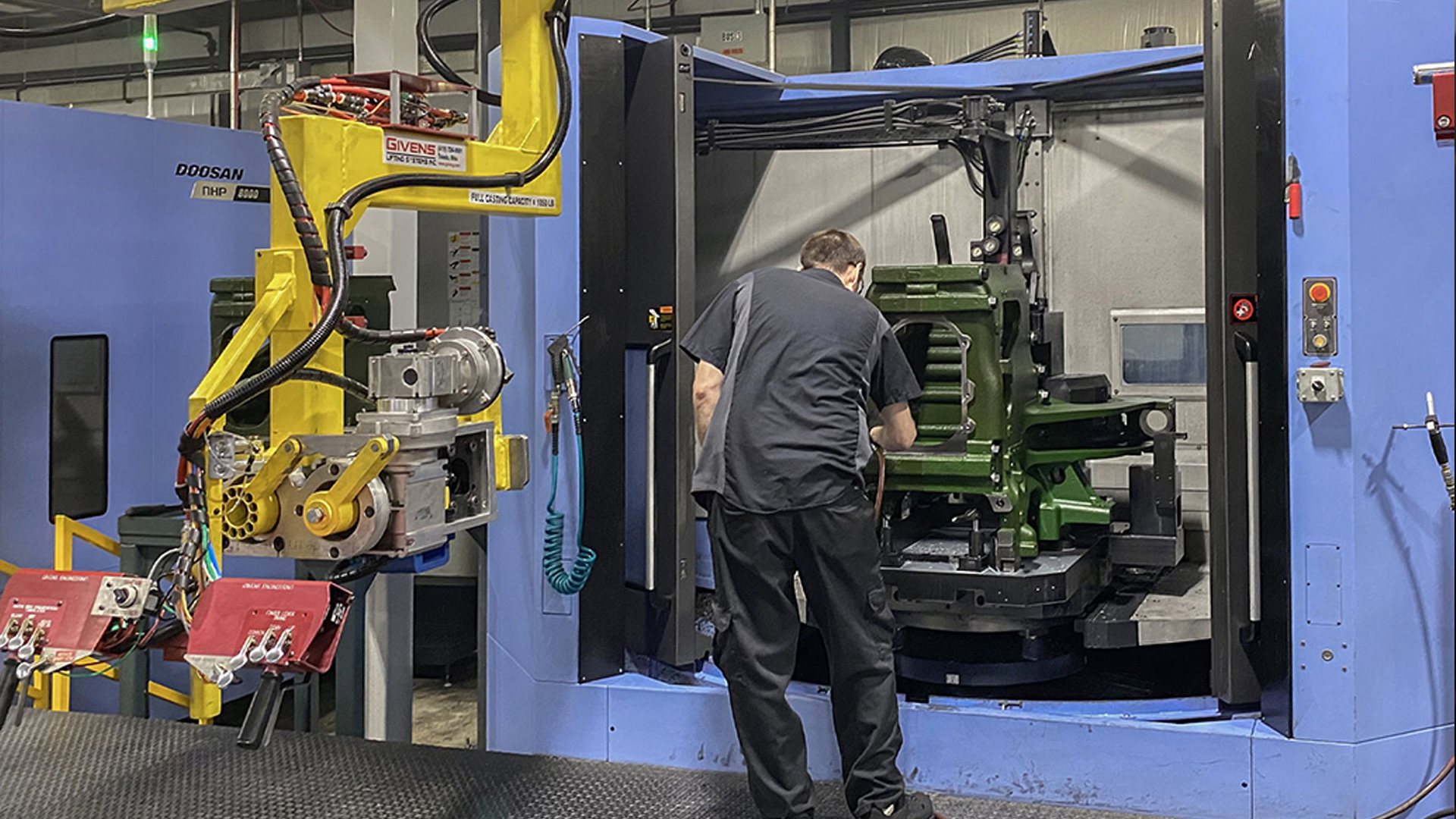

As a manufacturer and machine shop supporting a wide range of industries, it was important for TPM to continue to expand their machining capabilities and productivity. The PUMA SMX provided 9-axis capabilities while the DVF equipped with an automatic work changer (AWC) provided simultaneous 5-axis and automation capabilities. The PUMA TT was equipped with a barfeeder and offered twin turret, sub-spindle, y-axis, and lights-out automation capabilities. These added features allowed TPM to increase their productivity and profitability through automation and reduced operations and setups for simple and complex parts.

The 80-tool magazine is another big performance feature. Marv Rodriguez, VP of Operations, explains

“We had an air conditioning/cooler part for a major aerospace corporation that took four operations totaling about two hours of cycle time. With the PUMA SMX2600ST, it’s now down to 20 minutes per part in one operation.”

A DVF 5000 plus AWC (8 pallets) and 120-tool magazine is another recent acquisition. “We had a competitor’s 5-axis machine,” Todd said. “But we wanted something with a pallet pool.” The AWC gave the company an increase in capacity, reducing job setups for minimal turnaround time. “The 120-tool magazine capacity allows us to be tooled up and ready for any kind of work in the future,” Marv added. “That other 5-axis is getting closer to the exit door by the day.”

“We didn’t have any machines with bar feeds or twin turrets, it was new to us,” Marv said.

“But it’s been helpful for us to have both of those additions. Even with one less machine, we increased productivity by running more parts faster through the PUMA.”