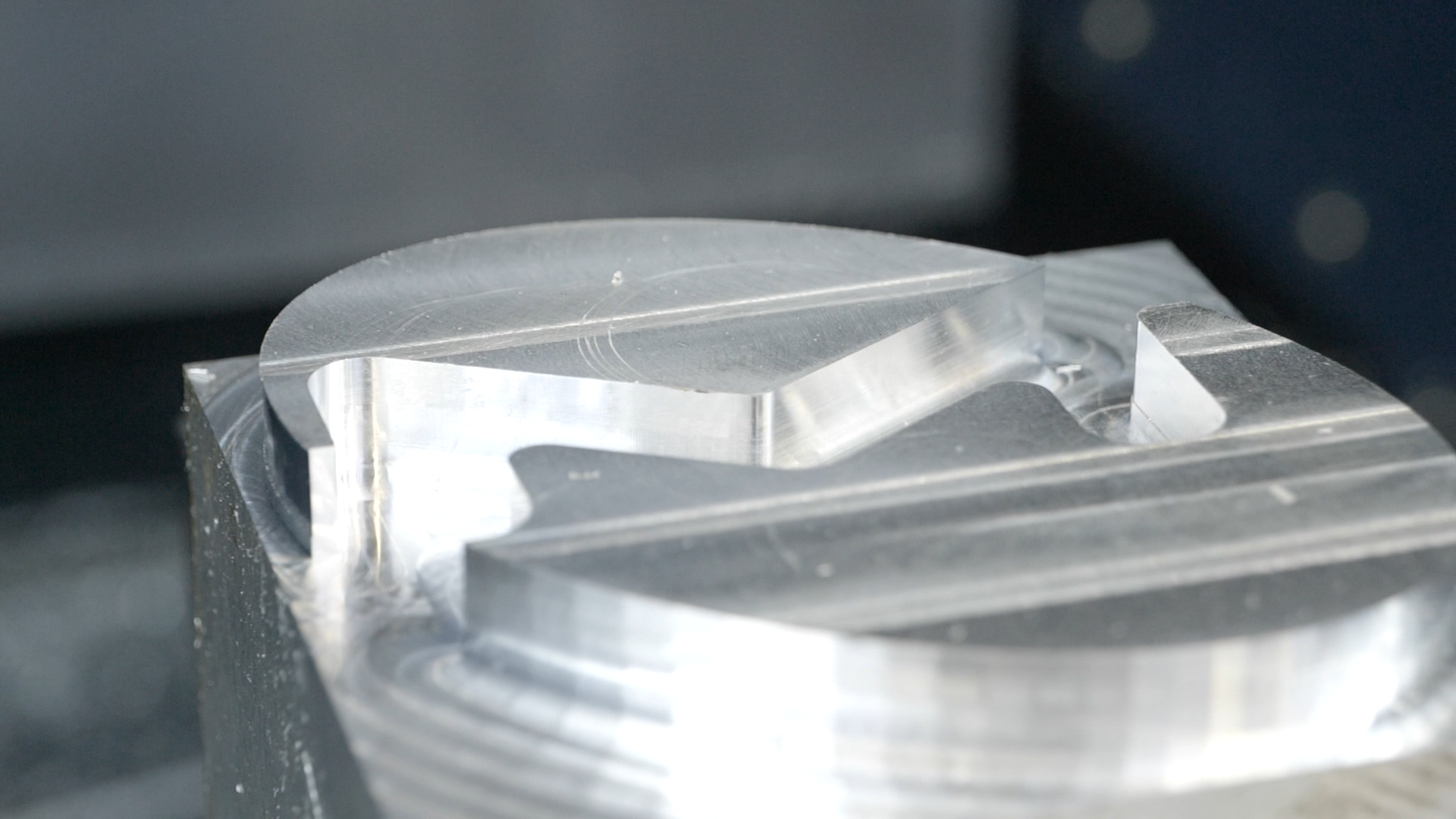

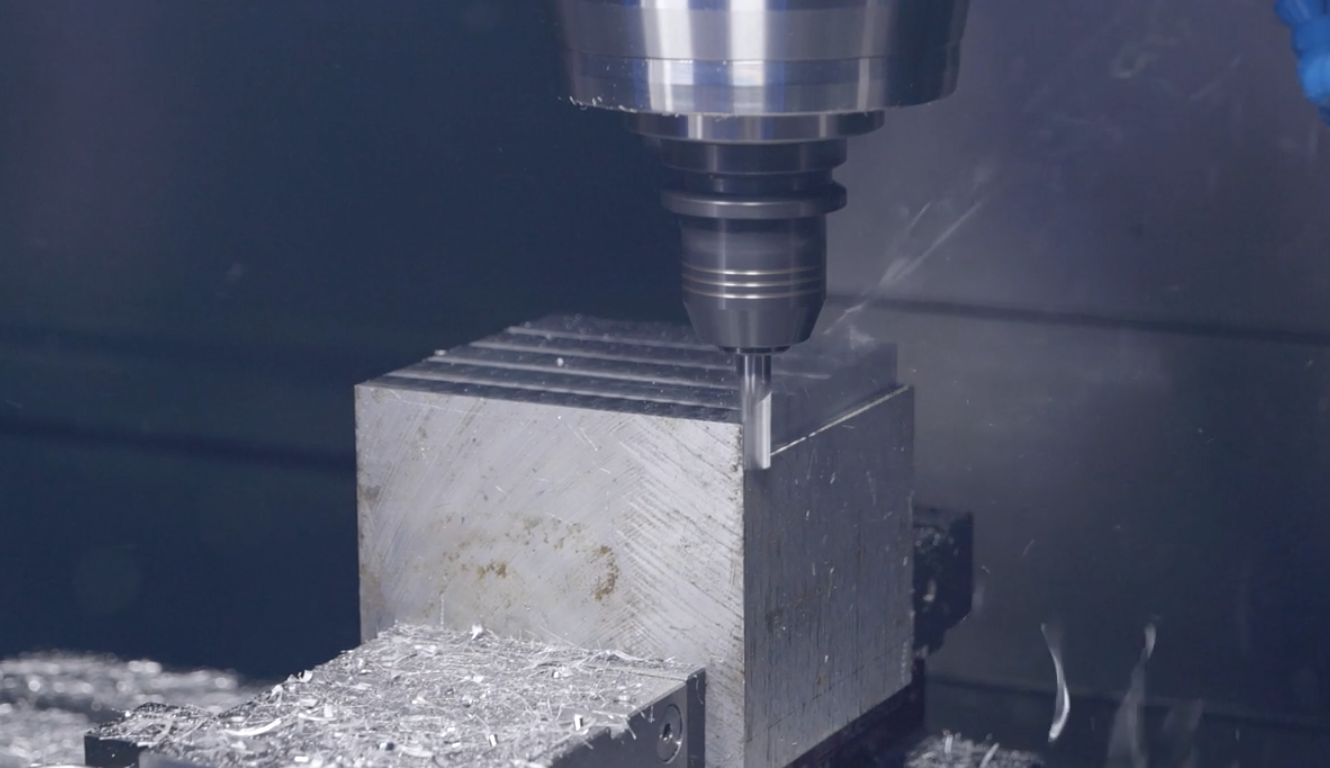

Takumi 5-axis CNC machines are designed for superior speed, quality finish and the accuracy needed for today’s industries. Their range of 5-axis machining centres cover both 4+1 and full simultaneous machining capability, the choice of model selectable on the size, contouring and positional features of the component.

Firstly, the smallest full 5-axis within the range, the U400, is a high speed 5-axis machining centre with high accuracy and outstanding surface finishes. To ensure a stable and powerful spindle the machine has a wider saddle. The T-shaped base is made of a one-piece casting and with a high-rigid mechanical structure to provide the best rigidity and stability.

Further into the series we have the U600 a full 5-axis machining centre which has exceptional high speed machining capabilities, accuracy and produces outstanding surface finishes. Take a virtual tour and see the machine for yourself – https://kuula.co/share/collection/7k5Gx?fs=1&vr=1&zoom=1&sd=1&initload=1&thumbs=1&info=0&logo=1&gcl=1

Takumi have been manufacturing prestigious machine tools for a long time and the U800 5-axis machining centre is a true reflection of this. The machine has many advantages like its high precision, excellent surface finishes and a wide base casting for better support, rigidity and geometry. The U800 comes with travels of 800 x 950 x 750 mm, table size ø800 mm, spindle speed 20,000 rpm, ATC 32 tools and rapid traverse rate – 48 m/min [X, Y, Z].

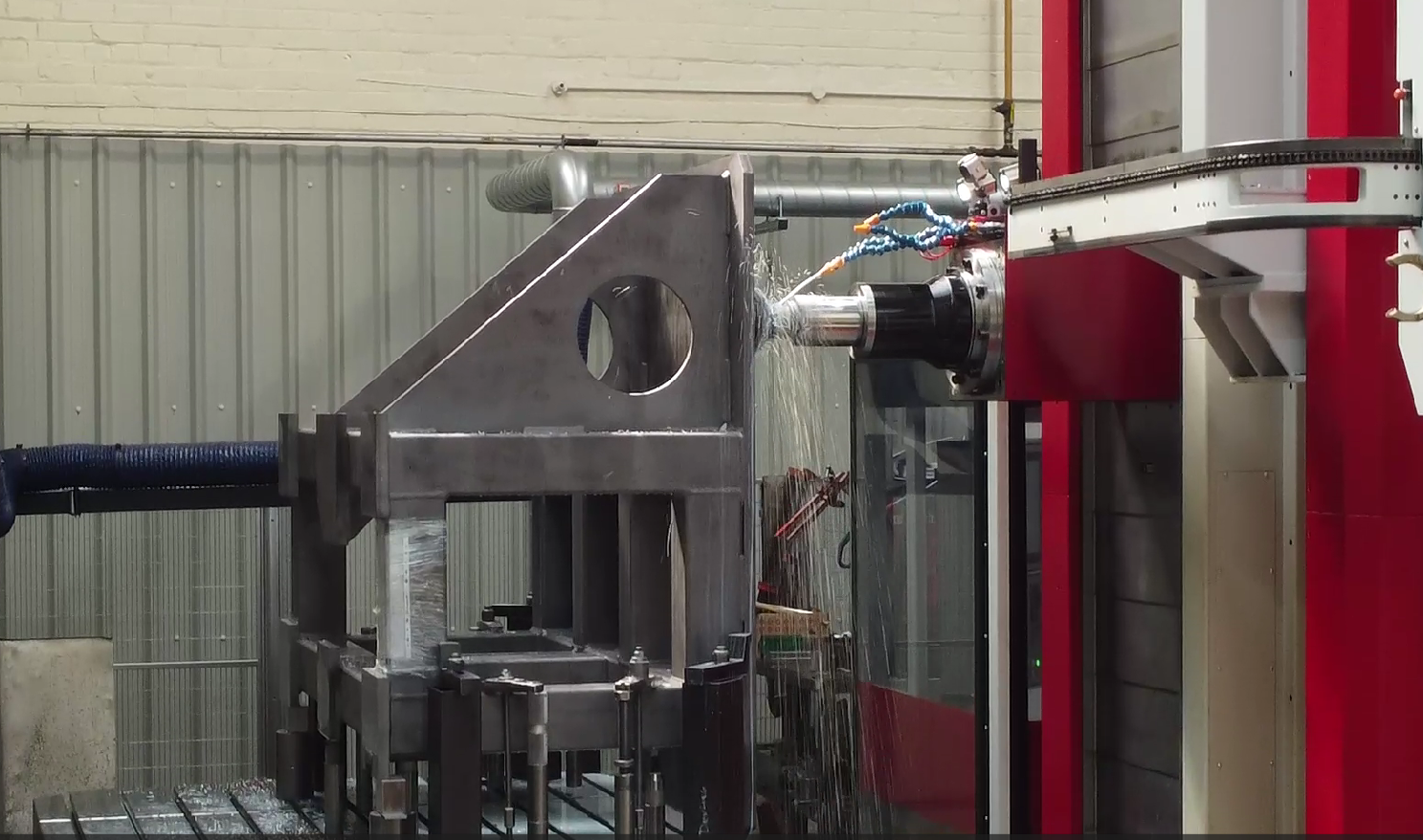

The UR1000 and the largest within the series. It comes with a motorised Italian swivel head spindle on a robust double column frame. The highly flexible UR1000 is available with a choice of either a 1400 mm C-axis rotary table, a dual combination of flat and rotary tables, or a 1600 x 1000 mm flat rectangular table.

The newest innovation that is available from Takumi is the UC320+, it is a double column machining centre. It is a compact machine, taking up less than 6M² of floor area, is ideal for machining high precision components weighing up to 200kg. The UC320+ is fitted with a Fanuc 0iMF Plus CNC control. The Ø320mm rotary table, rapid speeds of 36M/min in X/Y, absolute accuracy using linear/rotary scales and a 24-position tool changer all go to produce a highly flexible production centre. The 15,000 rpm BBT40 spindle is directly driven by a 15kW motor developing 119N.m (S3) of torque, giving the UC320+ the capability of impressive metal removal for such a small machine.

For more information on the TAKUMI range visit – www.leadercnc.co.uk/TAKUMI

Linkedin – www.linkedin.com/company/leader-cnc-technologies

Facebook – www.facebook.com/Leader-CNC-Technologies

Twitter – www.twitter.com/LeaderCNCTech