LEAP 71 Produces Large-Scale 2000 kN Rocket Injector Head Using Nikon SLM Solutions’ NXG 600E Metal AM System!

By Ashutosh Arora

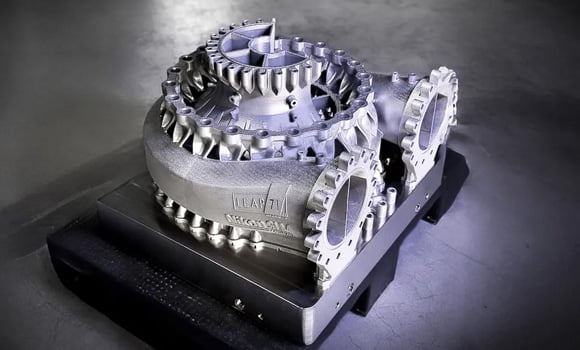

LEAP 71, a Dubai-based advanced engineering company, has achieved a major breakthrough in rocket engine manufacturing through its collaboration with Nikon SLM Solutions. Together, the companies have successfully produced a full-flow staged combustion (FFSC) rocket engine injector head delivering 2000 kN (2 Meganewtons) of thrust—one of the most complex and largest metal Additive Manufacturing (AM) spacecraft components ever created.

Manufactured on Nikon SLM Solutions’ industrial-scale NXG 600E metal AM platform, the injector head measures 600 mm in diameter and serves as a core component of LEAP 71’s XRB-2E6 methane/liquid oxygen rocket engine. This achievement marks a significant milestone in a partnership that began more than two years ago and demonstrates the power of combining advanced computational engineering with production-grade metal AM technology.

A key differentiator of this project is that the injector head was entirely generated by LEAP 71’s Noyron Large Computational Engineering Model—a physics-driven artificial intelligence system described as the “first AI that builds machines.” Operating without human intervention, Noyron generates highly complex, functionally optimized hardware directly from performance specifications. This allows LEAP 71 to design intricate propulsion components in hours rather than weeks, unlocking unprecedented iteration speed for next-generation rocket engines.

To withstand the enormous heat and pressure loads of a full-flow staged combustion cycle—widely considered the most efficient propulsion architecture—Nikon SLM Solutions produced the part using IN718, a high-strength, heat-resistant nickel-based superalloy used extensively in aerospace. FFSC systems push both methane and oxygen through the engine’s pre-combustion chambers in a high-energy state, requiring injector structures built with extreme geometric precision and material integrity.

Nikon SLM Solutions leveraged the NXG 600E’s large build volume and 12-laser configuration to complete the injector head in under four days using its IN718 PROD parameter set. Christoph Wangenheim, Head of Additive Material Products & Development at Nikon SLM Solutions, highlighted the difficulty of the project, noting how closely the two teams collaborated to fine-tune process parameters and optimize every step of the AM workflow. The result: a fully printed, highly intricate structure that meets the extreme demands of rocket propulsion—produced in record time.

For LEAP 71, metal Additive Manufacturing is foundational to its engineering paradigm. Traditional injector heads require the precision assembly of hundreds of individually machined components. By contrast, printing the component as a single monolithic structure dramatically improves reliability, reduces leak risk, increases design freedom, and cuts manufacturing time from weeks to days. The NXG 600E’s speed and scalability are essential to LEAP 71’s vision of rapid design–test–iterate cycles that continuously refine Noyron’s computational models with real-world feedback.

Josefine Lissner, Co-founder and CEO of LEAP 71, described Nikon SLM Solutions as the ideal partner due to its deep expertise and pioneering role in metal 3D printing. She noted that the NXG system’s multi-laser architecture enables the manufacturing turnaround times needed to match the speed at which Noyron generates complete rocket designs.

The XRB-2E6 engine is envisioned as a reference design capable of being computationally adapted for customer-specific launch needs. LEAP 71 is now working with global aerospace organizations to accelerate the development of high-performance propulsion and expand access to space.