Custom Tooling Solution Solves Legacy Part Challenges!

By Ashutosh Arora

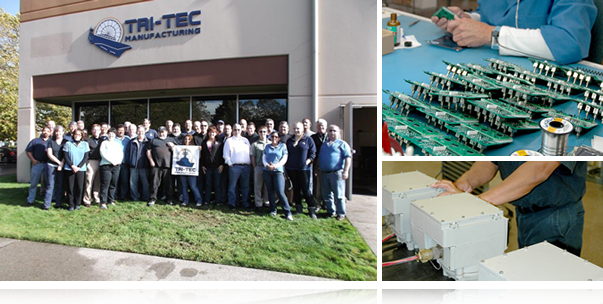

Tri-Tec Manufacturing, based in Kent, Washington, specializes in designing and building remote actuation assemblies such as vent valves and actuators used aboard U.S. Navy ships. These components, often integrated into critical safety systems like flood boundaries, must endure extreme conditions and remain serviceable for decades. The longevity of naval ships, often spanning 40 to 50 years, creates unique challenges for Tri-Tec, particularly when legacy parts require repair or re-machining but the original tooling is no longer available or supported.

Such a challenge emerged when Tri-Tec received a Navy actuator housing for repair. The job required re-machining a critical surface deep inside a manganese bronze casting, accessed through a narrow hole. The part was long-serving, but the original tooling was discontinued, leaving the team in need of a new, reliable solution. The answer came from Heule Precision Tool, known for its innovative back spot-facing technology.

Tri-Tec first turned to Heule when it purchased a B series 11 mm back spot-facing tool to replace an unsupported indexable back spot-facing tool. That initial solution proved effective, leading Tri-Tec to integrate Heule tooling into both repair work and new development projects. For a recent prototype, they selected a Heule BSF-A-0650/040-7.0 back spot-facing tool, which successfully handled a complex cut inside the actuator housing. The tool reached through a 0.257-inch access hole and machined a precise 0.520-inch flat surface on the far side of the part, even in a very tight space and under interrupted cutting conditions caused by a nearby raised boss.

Mark Smith, lead manufacturing engineer at Tri-Tec, explained that the company supports ongoing repair work across more than 20,000 unique part numbers, often in small batches of just 10 or 15 pieces. This job-shop-like environment requires flexible, reliable tooling that can adapt to varied geometries and materials while meeting strict Navy performance and durability standards. Smith noted that legacy parts frequently return for refurbishment years or even decades after they were first produced, making long-term tooling support essential.

The Heule tool offered several advantages. Its retractable cutter mechanism allowed the blade to pass through the narrow hole, expand to cut on the reverse side, and retract cleanly after machining. This eliminated the need for custom fixturing or multi-step setups, preserving accuracy and surface quality. To address the interrupted cut path, the Tri-Tec team adjusted feeds and speeds until the process stabilized, enabling them to achieve consistent results. According to Smith, once optimized, the tool performed flawlessly.

Although only two housings were prototyped before the design was modified, the success of the job demonstrated the potential for Heule tools in both legacy repair work and new product development. Tri-Tec now applies the same tooling solutions to remanufacture older components originally built decades ago, ensuring continuity and reliability in critical defense applications.

Smith emphasized that in industries like defense and shipbuilding, parts rarely disappear completely; they reemerge for service and repair even after decades. Having access to dependable tooling that remains supported over the long term allows Tri-Tec to meet the Navy’s stringent requirements and continue delivering parts that perform under the toughest conditions.