🎧Keeping the automotive industry moving

In automotive manufacturing, speed and precision aren’t luxuries—they’re survival tools and ‘every turn of the spindle counts’. Threading, grooving, and deburring may seem like small elements in the bigger picture of vehicle production, but get them wrong, and entire lines grind to a halt.

Few tooling providers have tuned their offering so tightly to the demands of this environment as VARGUS. With its VARDEX threading systems, GROOVEX grooving solutions, and SHAVIV hand deburring tools, VARGUS has positioned itself as a crucial partner to the automotive industry and the supply chain around the globe.

From transmission cases to ‘e-axle’ housings, automotive driveline components depend on precise threads and flawless sealing grooves. The VARDEX threading tools handle high-volume work in ductile iron, aluminium, and alloy steels with remarkable repeatability, whilst the GROOVEX tools can cut retention and O-ring grooves with predictable and stable tool life—keeping scrap rates low in critical sealing areas.

This process stability is critical in high-output environments; a single defective groove or off-spec thread can trigger costly line stoppages, and manufacturing sites running modular VARGUS systems frequently report reduced tooling SKUs, faster changeovers, and fewer burr-related rework and post-operation hand finishing.

The rise of electric vehicles has reshaped machining challenges with the arrival of thin-wall battery trays, intricate coolant channels, and delicate motor housings. Thread milling is known to minimise cutting forces, which protects lightweight aluminium structures from distortion. It is here that the compact GROOVEX tools from VARGUS enable intricate sealing features in cramped, high-value components. The result is faster adaptation to evolving EV designs without complete retooling.

Manufacturers notice the difference with predictable tool life that reduces unplanned production stoppages and makes OEE more stable. Consistent quality is also maintained with micron-tight profiles maintained over long runs. Additionally, end users have simplified inventory with fewer unique SKUs for threads and grooves. In addition to this, VARGUS has a range of digital tools available through its application software that has become a secret weapon for engineers in APQP and PPAP phases. With it, teams can select the right tool by standard, pitch, and material and also access proven cutting data with the added benefit of generating tool strategies quickly with cutting ‘trial-and-error’ time before production launch.

Automotive manufacturing is a balancing act of volume, accuracy, and efficiency. VARGUS’s precision tooling and digital support help manufacturers keep that balance, turning once-fragile processes into robust, repeatable production steps. In a sector where every second matters and quality is king, VARGUS has become more than a tooling supplier—it’s a partner in keeping the wheels of industry turning.

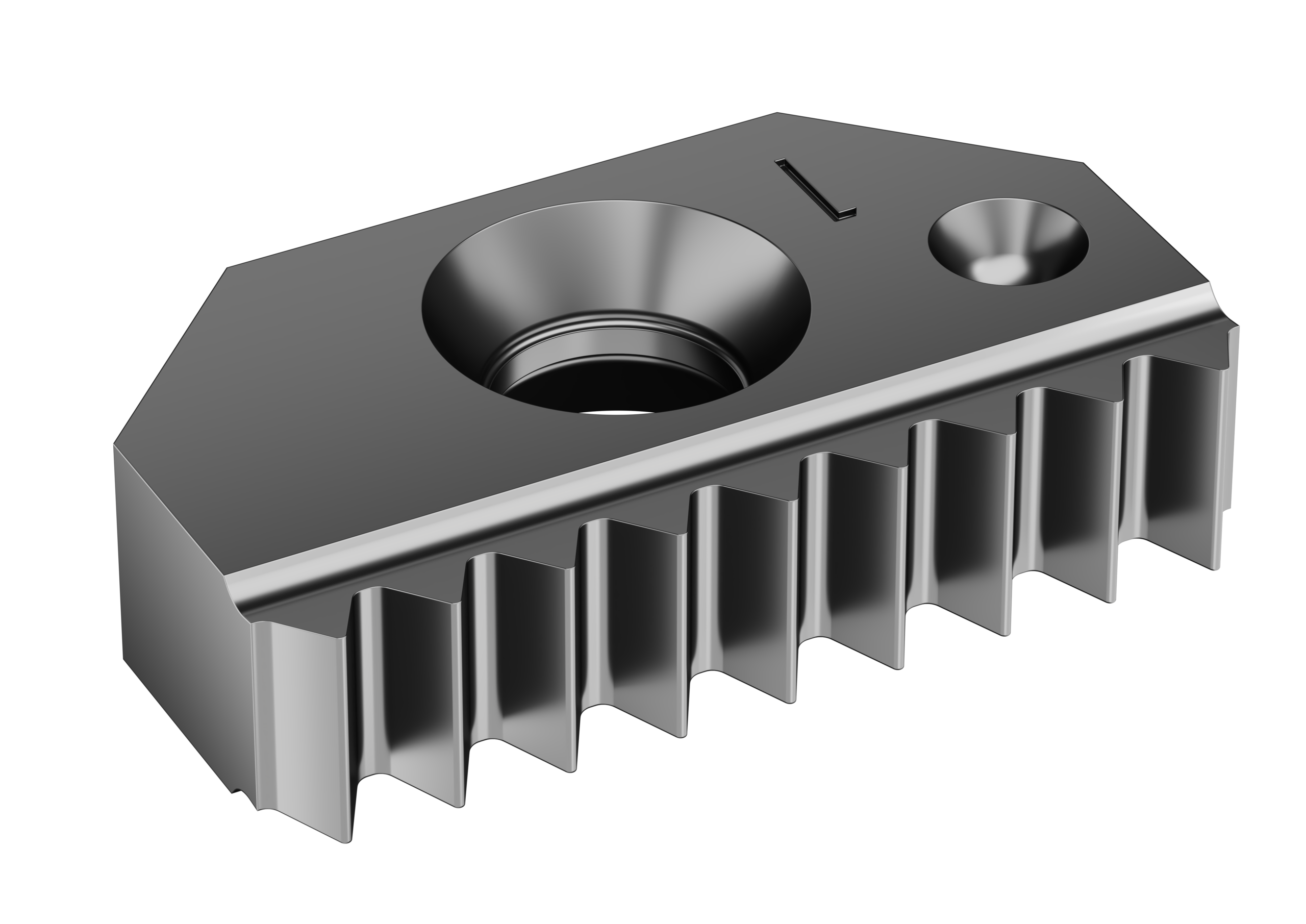

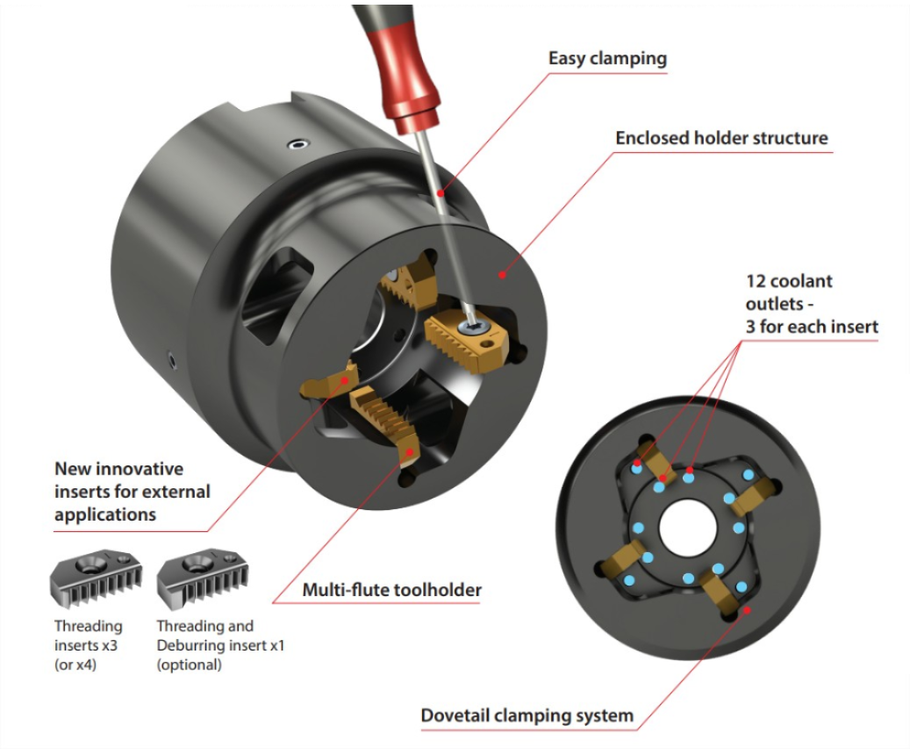

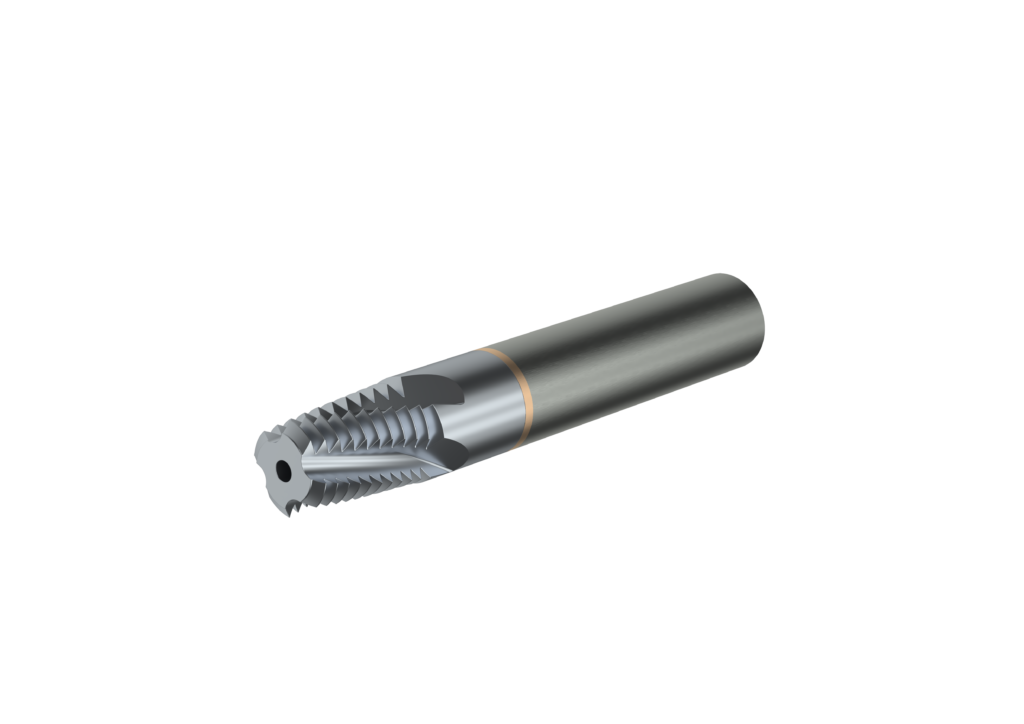

The latest addition to the company’s portfolio is the new VARGUS bell shape tool, a high-speed external threading system designed for the automotive and valve industries. Suitable for threading manifolds and fuel filters with extreme precision and cycle times, it features short toolholder movements, multi-flute toolholders, easy clamping, a dovetail clamping system and an enclosed holder structure. All this delivers shorter cycle time and higher productivity, faster feed rates, convenient insert assembly, improved rigidity and accuracy and much more.