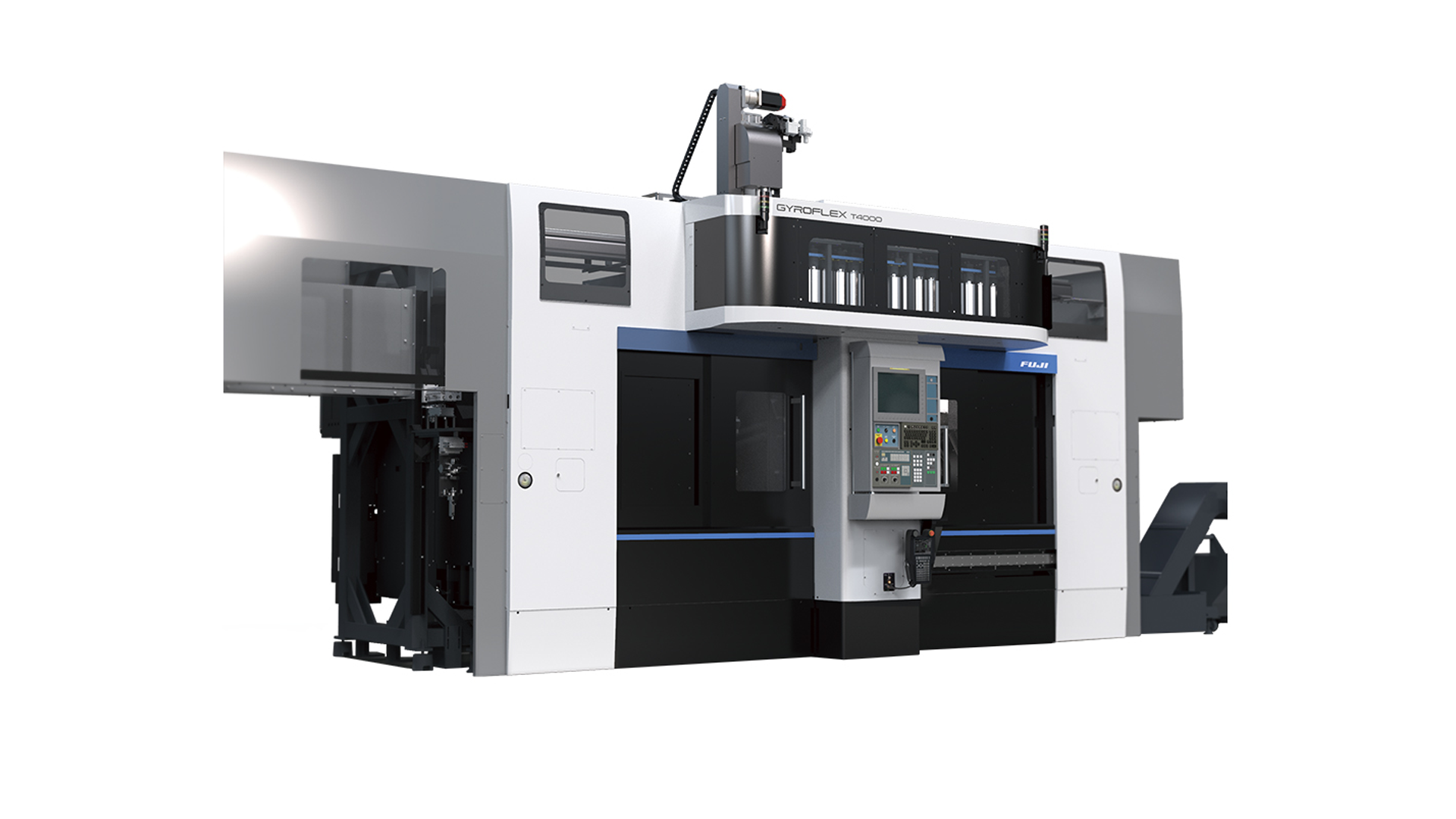

Featuring the latest industry-leading technology, the GYROFLEX is designed for unprecedented flexibility, efficiency and accuracy.

The GYROFLEX offers the flexibility to meet a variety of production demands, from low production volume and parts prototyping to high-volume and high-mixed production. A single GYROFLEX requires reduced setup and changeover times and completes complex parts efficiently and accurately.

The machine’s integrated Fuji-built LX-40 3-axis gantry robot enables unattended operation and fast parts handling. The hydraulic robot chuck provides stable clamping and workpiece handling using minimum space thanks to the innovative thin-type double hand design. Easy programming for complex parts and process combination are made possible with an ESPRIT 3D CAD/CAM system. In addition, the perfect chip disposal design enables non-stop production.

The GYROFLEX’s opposed twin spindles are positioned on Z-axis slideways with 960mm of stroke. Equal in size and capability, each spindle is capable of performing the same operations (OP-10A/10B). The Z-axis slide moves at high speeds to reduce loading time to the second spindle.

A milling tool spindle, mounted on rigid X and Y axes box way slides, allows for various types of machining by accessing both Z-axis spindles and swinging up to 190 degrees. Milling tool spindle speeds reach 12,000 rpm with a 15 HP spindle motor. A 15-station live tool turret, also positioned on highly rigid X & Y axes box way slides, offers indexing times of 0.4 sec. and spindle speeds of 4,000 rpm max. with a 6 HP spindle motor.

The GYROFLEX ATC rapid tool change time is 4 sec., maximum tool diameter is 130mm, tool length is 300mm and tool weight is 8 kg. Fuji’s GYROFLEX features a 40-tool ATC and a Fanuc 31i-B Plus controller. The machine footprint is 5000 x 3000mm (16’5” x 9’10”) and height is 3530mm (11’7”).