Logical extension

Some years ago, ISCAR launched its LOGIQ product line, a campaign that brought new families of cutting tools to the world market. The product families were designed to address challenges that range from increasing productivity to finding cost-effective indexable alternatives to small diameter solid carbide tools.

Now, ISCAR introduces NEOLOGIQ, the company’s logical extension to the previous campaign that comprises an entire range of advanced products and technological solutions for metal cutting tools.

What are the main targets of the NEO product lines?

ISCAR believes that NEOLOGIQ provides the answers to typical questions that the modern metalworking industry faces. Today, we are witnessing serious upheaval with far-reaching effects on manufacturing. A distinct course for electric and hybrid cars will lead to a gradual abandonment of traditional internal combustion engine cars and the respective parts that need to be machined.

A rise of accurate metal shaping methods, such as precision investment casting, precision forging and 3D printing, are all capable of shaping a part very close to its final profile. This significantly diminishes the stock that is traditionally intended for chip-removal processes. A logical result of this is the considerably reduced share of machining operations in a part manufacturing cycle and this trend is already noticeable in the market today. Does it mean that a few good metalworking shops, factories, or even whole branches will abandon machining?

Of course not, but the requirements for machining in engineering processes will change. The role of productive and accurate cutting with a small allowance at high speeds and feeds will substantially grow, and industries will require a wide range of suitable tools that are expected to be more precise and durable.

Digitised manufacturing, which is dictated by Industry 4.0 momentum, has its demand and expects a new level of cutting tool ‘intellect’ to be suitable for smart manufacturing. In preparing for the upcoming changes, ISCAR considers NEOLOGIQ as the next logical step to the cutting tool for the smart factory. ‘Machining with no Boundaries’ is the motto of ISCAR’s NEOLOGIQ products. How do we overstep the customary boundaries of metal cutting?

Logical Milling

High-feed milling (HFM) is considered a commonly used effective method for rough machining of both complex and plane surfaces. ISCAR has an extremely wide range of HFM products to meet the requirements of the market. However, even in this niche range of products, there is space for innovation.

LOGIQ4FEED, a family of high-feed milling cutters carrying specific bone-shaped inserts, was enriched by new tools with greater insert sizes. These new tools have several features that substantially improve performance in high-feed milling, especially when machining large cavities and pockets in steel parts.

Another HFM product that provides a cost-saving solution is NEOFEED, a family of mills with square, double-sided inserts. This insert has 8 indexable cutting edges and a dovetail-shaped insert pocket that ensures reliable mounting to withstand heavy loads that enable higher cutting data and increased productivity.

The progress in 5-axis machining and CAD/CAM systems open new horizons for machining 3D surfaces using barrel-shaped end mills. Although such end mills are not common, advanced accurate metal shaping methods will dramatically increase the demand for these barrel-shaped end mills. Therefore, the development of effective ‘cutting barrels’ is one of ISCAR’s highest priorities. In the NEOLOGIQ product range, the barrel-shaped endmills are represented by two configurations: a solid carbide design and a MULTI-MASTER head. Combining MULTI-MASTER advantages with the precise barrel profile of a cutting-edge will result in a cost-effective and sustainable solution for finishing complex-shape surfaces by milling with minimum machining stock.

The MULTI-MASTER family has expanded the boundaries of its product range by introducing a new threaded connection size. The T21 enables users to increase the nominal diameter of an exchangeable end mill head to 32mm.

Intelligent Turning

Intelligent Turning

With internal turning, the boring bar is the main factor of tool rigidity. A large bar overhang to diameter ratio leads to tool deflection and vibration; and is the bane of machining accuracy and surface finish. WHISPERLINE, a family of anti-vibration boring bars was developed to exceed the ratio boundaries. These bars have a specially designed built-in vibration-dampening mechanism that enables stable cutting with an overhang of up to 14XD.

WHISPERLINE bars are important elements of the new versatile modular system NEOMODU. It provides a rich variety of assembly options for turning tools. A combination of different system units such as shanks, anti-vibration capsules, and interchangeable heads with indexable carbide inserts result in a tool assembly that is maximally customised to a specific application. The shanks may be cylindrical, square or with a polygon taper interface following ISO: 26623.

Also from the turning stable is the new XNMG insert which is a beneficial combination of two ISO rhombic insert shapes, the CNMG and DNMG inserts with 80° and 55° included angles. This intelligent integration results in the XNMG 70° angle insert that features improved clearance and ramping angles when compared to the CNMG. It also demonstrates strengthened cutting performance over DNMG inserts. The advantages of the new insert are visible in efficient multi-directional turning applications. The cartridges carrying the XNMG insert are intended for mounting on NEOMODU units.

Competent Parting

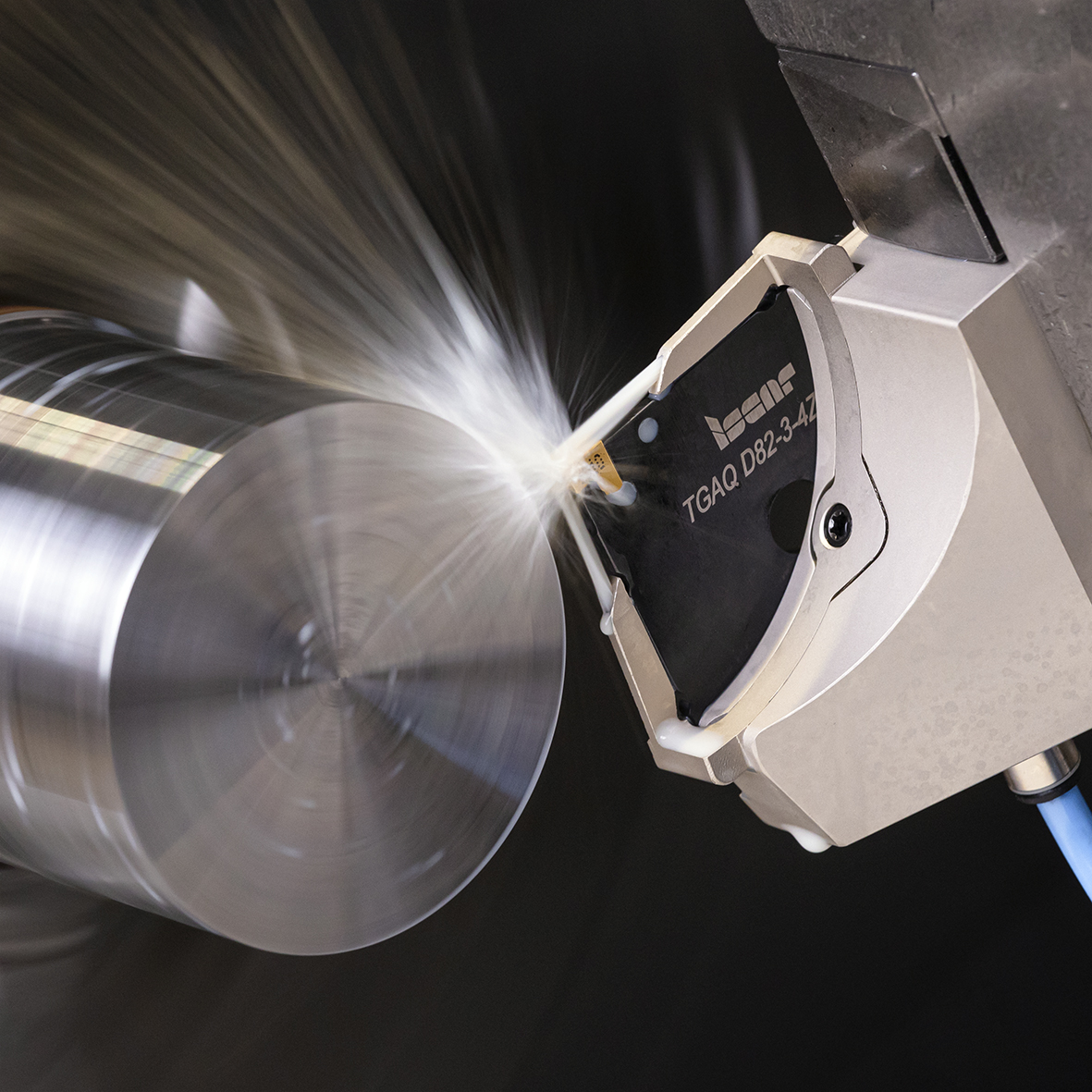

ISCAR has a firm foundation in parting tools and that is why its innovations in parting gain special interest. Adapters and holders occupy a prominent place among ISCAR’s NEOLOGIQ parting products and the concept of the LOGIQFGRIP family is based on a 4-pocket adapter that is clamped in a reinforced tool block. The high rigidity of such an assembly in combination with an inner high-pressure coolant supply (HPC) option facilitates productive cutting with extremely high feed rates.

In parting, one of the secrets to success is well-directed high-pressure cooling (HPC). If an adaptor has no HPC channels, mounting a specially designed crown-shaped accessory pushes the boundaries of application limits and enables effective pinpointed coolant flow to the active cutting edge of an insert.

The growing capabilities of modern multi-tasking machines and turning centres push the common boundaries of cutting strategies. Particularly, they brought the method of efficient turning along the Y-axis. In quite a few cases, it is a worthy alternative to traditional X-axis machining. In Y-axis turning, the dissipation of cutting force components is more favourable, and the main load is directed to a holder. The cutting process becomes more stable, and this facilitates increased cutting data to improve productivity. Therefore, providing appropriate cutting tools for turning operations along the Y-axis is one of the central points of NEOLOGIQ.

Efficient Holemaking

One of the more impressive product lines is LOGIQCHAM, a family of drills with replaceable carbide heads and three cutting edges, providing an effective tool for significantly increasing productivity for drilling depths up to 5XD. When drilling, efficient chip evacuation is extremely important. It is not enough to optimise chip control with an advanced design of the head geometry. The flute shape should ensure seamless chip flow. Undoubtedly, three grooves weaken the body, and when compared to a two helical flute drill of the same diameter, the three-flute body is less rigid. When the depth grows, longitudinal vibrations may occur, and this reduces tool life and adversely affects the accuracy and roughness of a machined hole. A new three-flute drill body design is based on a variable flute helix angle. Such a concept considerably improves the dynamic behaviour of the drill and results in expanding the drilling depth boundaries – the maximum depth can now reach eight diameters.