OPEN MIND Technologies has now launched the latest version of its hyperMILL® CAD/CAM software, Version 2022.1. The latest release will incorporate more features, optimised strategies and a host of enhancements for more powerful and simplified machine and controller independent programming.

With new optimisations to hyperMILL® such as 5-axis strategies in VIRTUAL Machining, Version 2022.1 will provide users with better results in terms of surface quality, new options for 2D functionality as well as efficient innovations in electrode manufacturing.

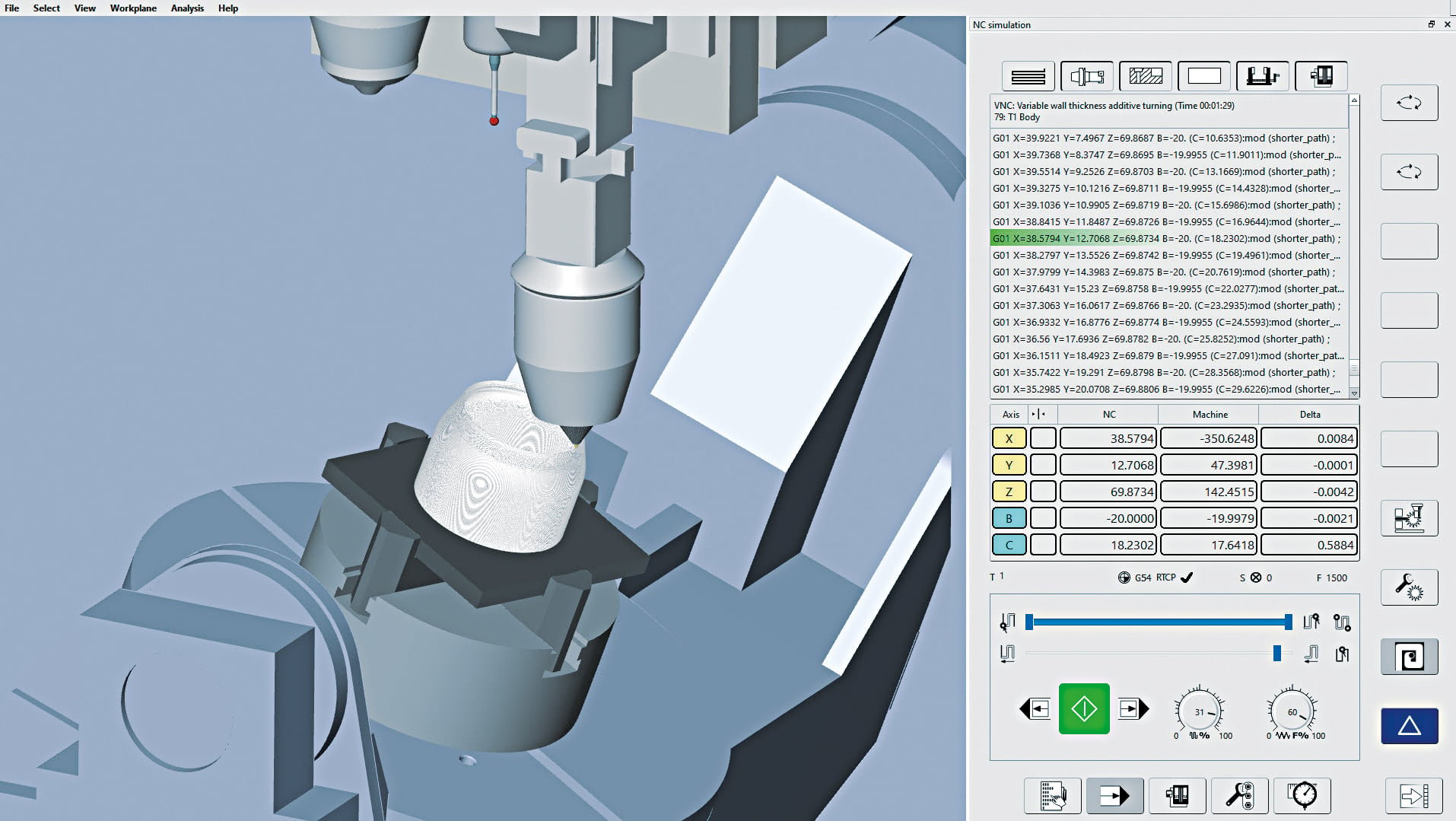

Virtual Machining can be used to map all process steps in CNC manufacturing for perfect process control. The modular technology now also supports additive machining programs. The Optimizer module, which delivers powerful optimisation algorithms for efficient multi-axis machining, also features the ‘Optimized Table-Table Logic’ function for reduced air time between cuts. The user selects a distance value, and the Optimizer automatically calculates the safety distances using the raw part, component and clamps selected in the job list.

Seamlessly merging the virtual and real world

The three hyperMILL® VIRTUAL Machining modules for the seamless merging of the virtual and real worlds form the core of the safe simulation solution. The Center module virtually maps real machining situations for the machine and controller and simulates these based on the NC code. The Optimizer module provides powerful optimisation algorithms that ensure efficient multi-axis machining. It also automatically identifies the best inclination for top machining results. The CONNECTED Machining module enables in-depth networking and synchronisation with the machine.

Machining strategies for 2.5D, 3D, HSC, Mill/Turn and 5-axis applications offer the ideal solution for any machining situation. In the area of 5-axis radial machining, new improvements raise the bar in blow mould machining. The new ‘Flow Equidistant’ infeed strategy is the first of its kind that supports the generation of toolpaths with a constant infeed for vertical and challenging surfaces. This means that these surfaces can be integrated into the overall machining sequence and processed in a single step to provide seamless machining with a very high surface finish quality.

A dedicated 3-axis machine mode greatly simplifies the use of radial machining on these machines, and the ‘Smooth Overlap’ function can be applied to the general milling area without selecting a boundary curve. For instance, the ‘Smooth Overlap’ function blends the transitions between two surfaces that have been milled in different machining directions. This results in perfectly transition-free surfaces.