AFRC and ATI Inc. Forge Partnership to Advance Sustainable Aerospace Materials!

By Ashutosh Arora

ATI Inc. has officially become a tier one member of the University of Strathclyde’s Advanced Forming Research Center (AFRC), marking the start of a collaborative effort in advanced engineering and materials science aimed at promoting sustainability in the aerospace industry.

ATI Inc., a prominent producer of materials for global aircraft engine manufacturers, specializes in creating high-performance materials and component solutions. Their portfolio includes titanium and nickel superalloys designed to withstand extreme conditions, such as high temperatures, pressure, and corrosion, which are critical for modern aerospace applications.

As part of this partnership, ATI will gain access to the AFRC’s cutting-edge FutureForge facility. This state-of-the-art forging research center provides an industrial-scale, isothermal testing platform that will support ATI in developing the next generation of materials and process technologies. With the aerospace sector increasingly prioritizing sustainability, the development of metallic alloys capable of enduring higher temperatures is essential. These advanced materials will enable jet engines to operate more efficiently, reducing fuel consumption and minimizing environmental impact.

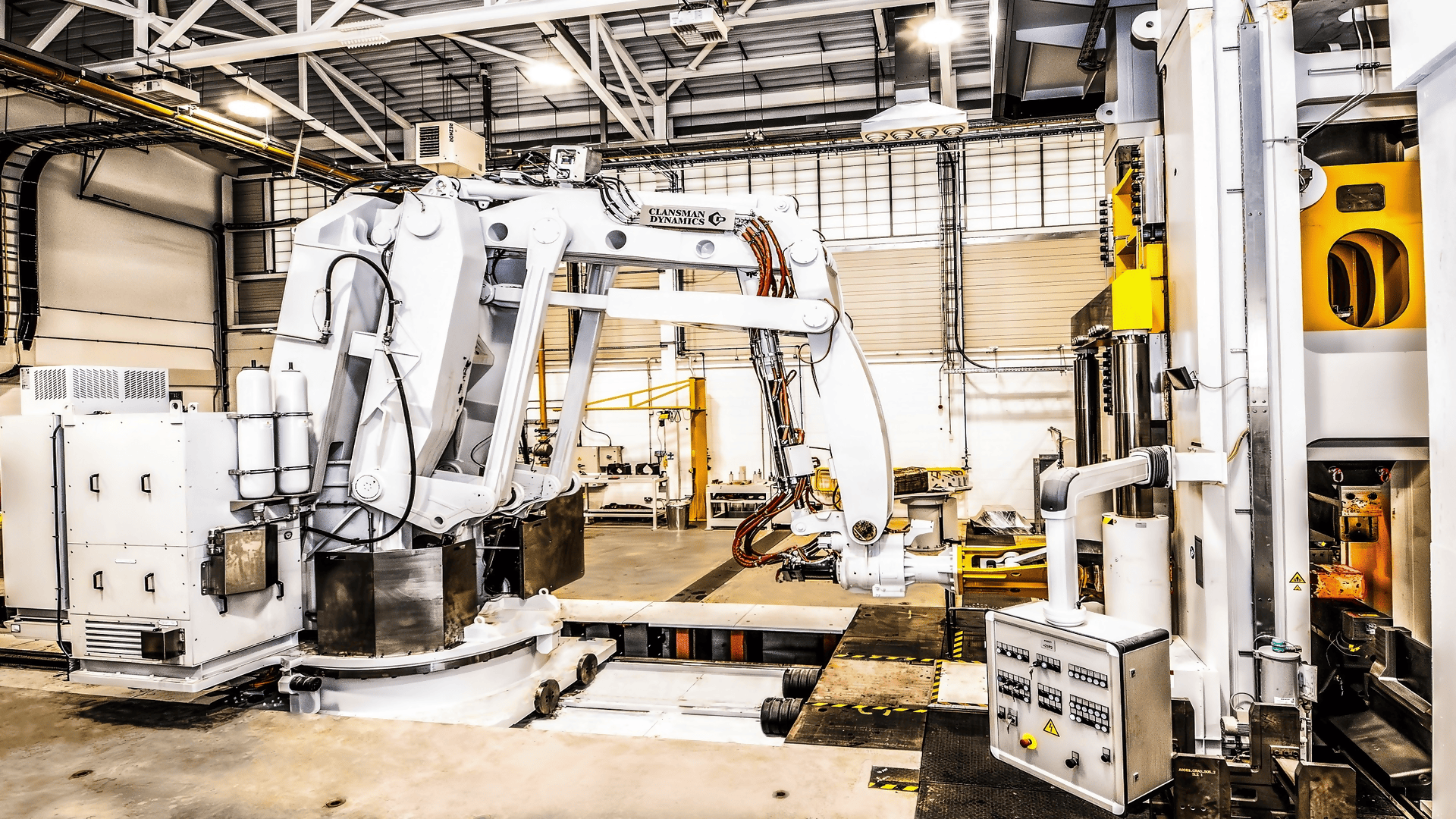

Launched in early 2024, FutureForge connects the global forging industry with the AFRC’s extensive expertise and advanced testbed capabilities. The facility boasts a tri-modal 2,000-ton press that offers open die, closed die, and isothermal forging capabilities, along with quick data analytics through its control room. Additionally, FutureForge is equipped with two furnaces—one electric and one gas-powered—and a custom-built smart robotics manipulator arm. These features allow companies like ATI to mitigate risks associated with developing new products, processes, and technologies.

“Aerospace is a hugely important sector for the global economy, and materials science is key to developing the next generation of aircraft engines that can operate more sustainably,” said Professor Brad Wynne, Director of the AFRC. “With FutureForge, the AFRC is uniquely positioned to help develop these novel materials, offering an industrial-scale testbed unparalleled in the industry. The collaboration with ATI, whose team is primarily based in the USA, underscores the international strength of our facilities and research expertise.”

ATI stands alongside global giants such as Rolls-Royce and Boeing as one of only seven tier one members of the AFRC. As part of this elite group, ATI representatives will join the managing and technical boards of the center, providing them with greater influence over future research programs and opportunities to collaborate with other leading members.

“ATI has the ability to perform end-to-end across the entire jet engine supply chain,” said Jim Meudt, Vice President of ATI Global Commercial Strategies. “As a member of the AFRC’s managing and technical boards, we’ll collaboratively share our expertise and learn from others to accelerate innovation in our industry.”

This partnership between AFRC and ATI Inc. signifies a significant step forward in the quest for sustainable aerospace technologies. By leveraging the advanced facilities and collaborative environment of the AFRC, ATI is poised to drive innovations that will enhance the efficiency and environmental performance of future aircraft engines.