EMO Milano has come to an end and the exhibition has always been known for being one of the leading trade shows for world manufacturing and it certainly showed this with the number of visitors that arrived to see the latest technologies and innovations.

The show consisted of six halls in total that covered 100,000 sq. meters and over 3,500 machines from different brands for visitors to see, a value exceeding half a billion euros. With all of these technologies available to see they were being shown by exhibitors from 34 different countries.

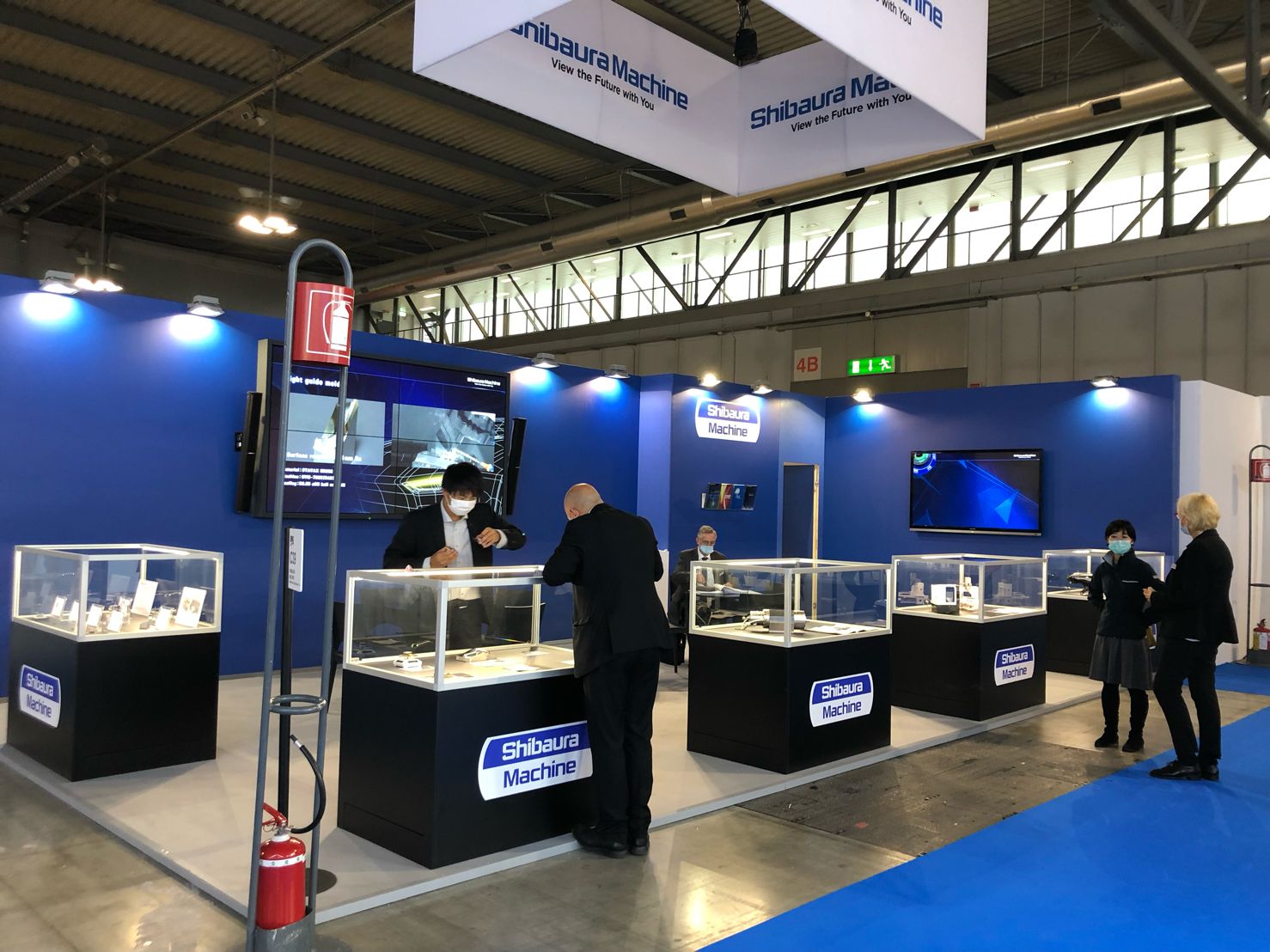

Two of our principals attended this year’s exhibition, Italian manufacturer Gruppo Parpas and Japanese manufacturer Shibaura Machine [known previously as Toshiba Machine].

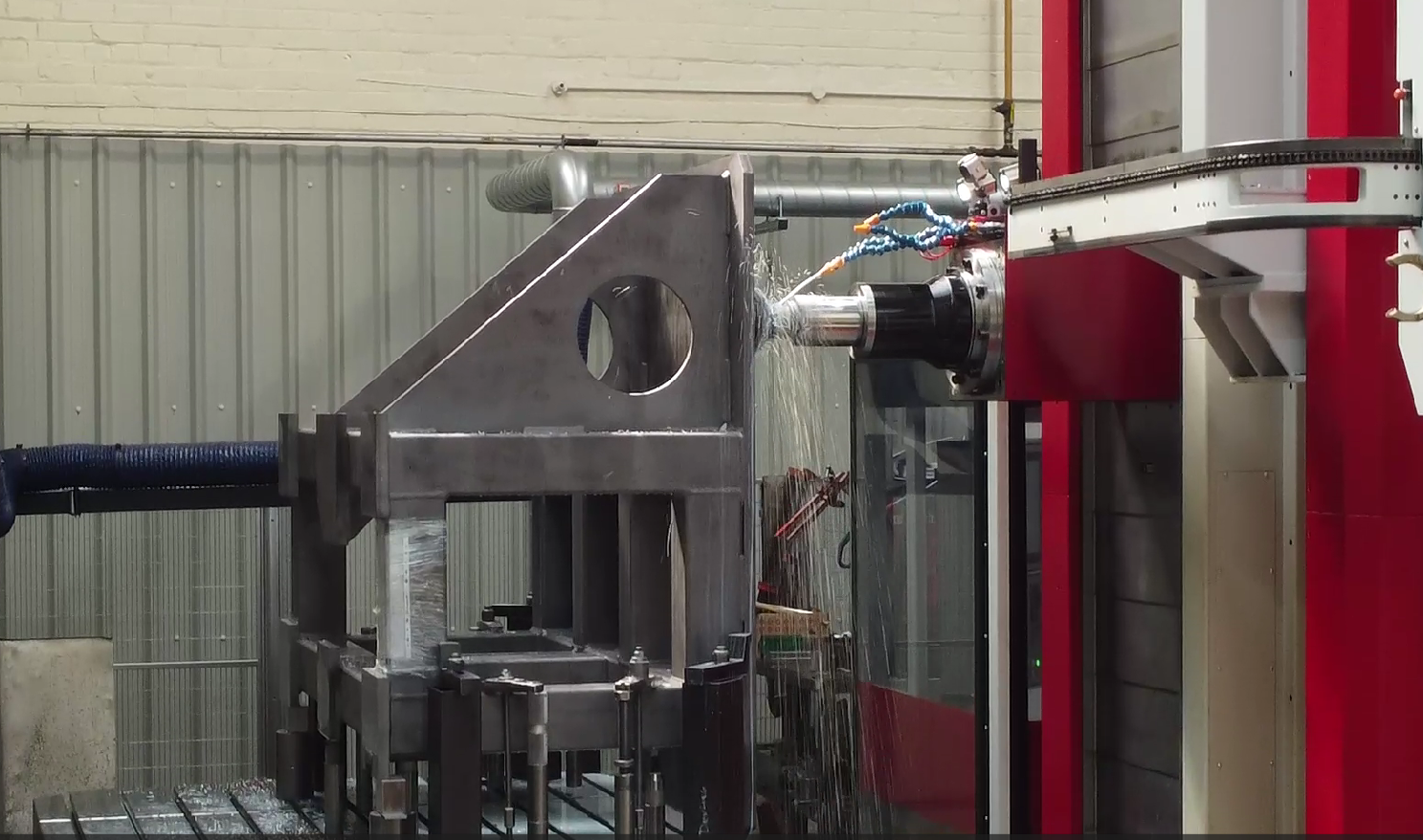

Firstly, Gruppo Parpas are a prestigious machine tool manufacturer with an incredible engineering team and their vast amounts of knowledge in engineering is shown through what they presented at this year’s show. Their stand consisted of three large machine tools the Active Five Linear, Speedliner and their newest machine tool the Manta. The Manta moving column machine is their latest innovation offering more to their portfolio as well as more options to manufacturers.

The Speedliner is a gantry mill and has the capability for 3 or 5-axis high-speed machining, especially useful in the aerospace and mould/die sectors. This quality machine tool features a monobloc gantry style structure with a moving saddle and a stationary workpiece.

Their final machine available to visitors was the portal milling centre the Active Five Linear which is available in two derivatives, standard and linear. The latter achieving 60 M/min, truly impressive for a machine of its size. The maximum table size available is 4.1M x 1.1M and is capable of carrying a 5,000kg load. The cooled and temperature-controlled 5-axis head makes the Active highly suitable for continuous machining of mould/die and aerospace components.

Shibaura Machine also attended the exhibition with their newest innovations, such as their nanotechnologies.

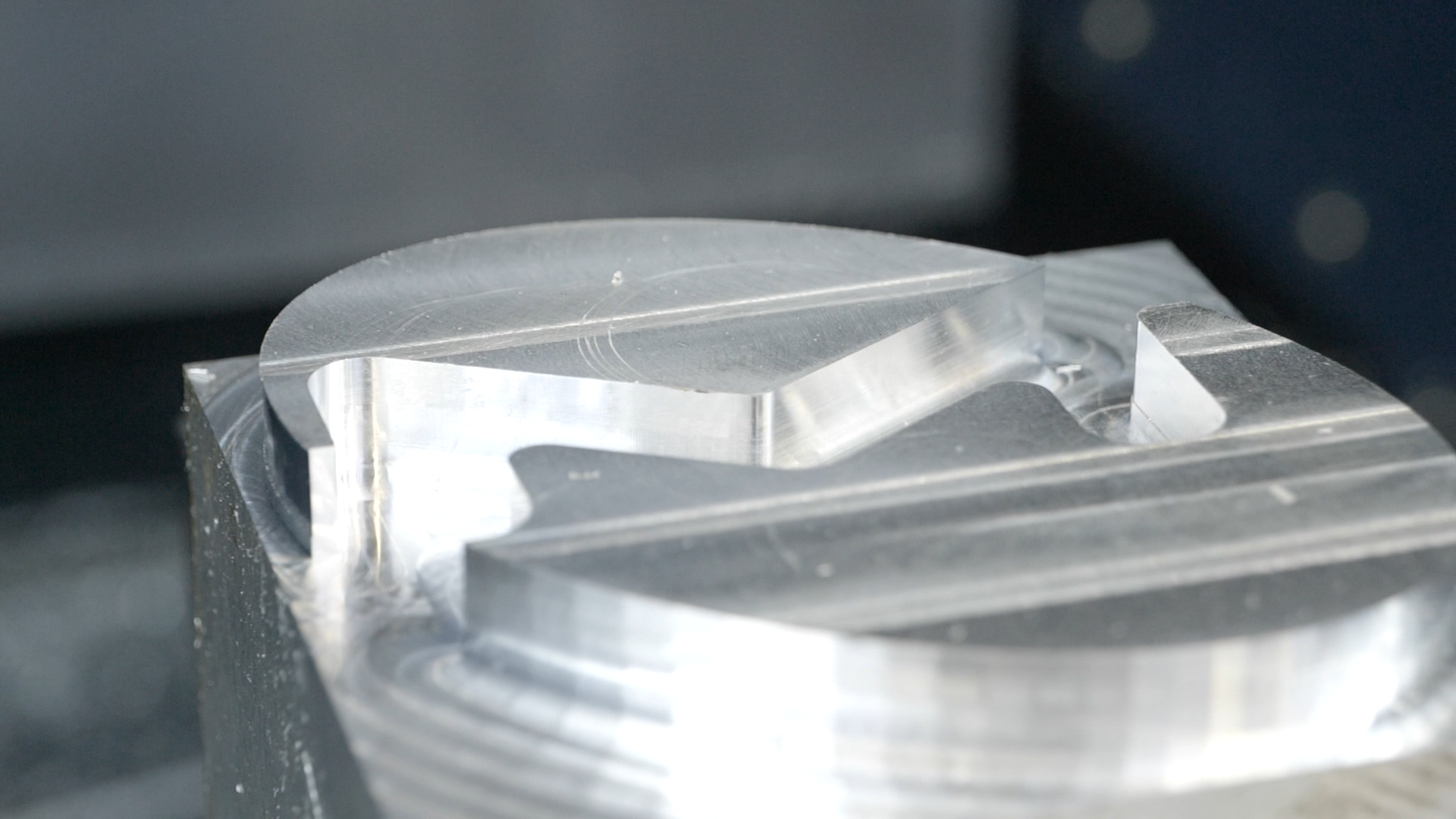

As new technologies, materials and products impose tighter controls on complex components, milling and grinding to sub-micron accuracies and mirror-like finishes are coming to the forefront.

Shibaura Machine, formerly Toshiba Machine, envisaged these changes many decades ago and have since continued to develop and improve their range of super accurate Nano machine tools.

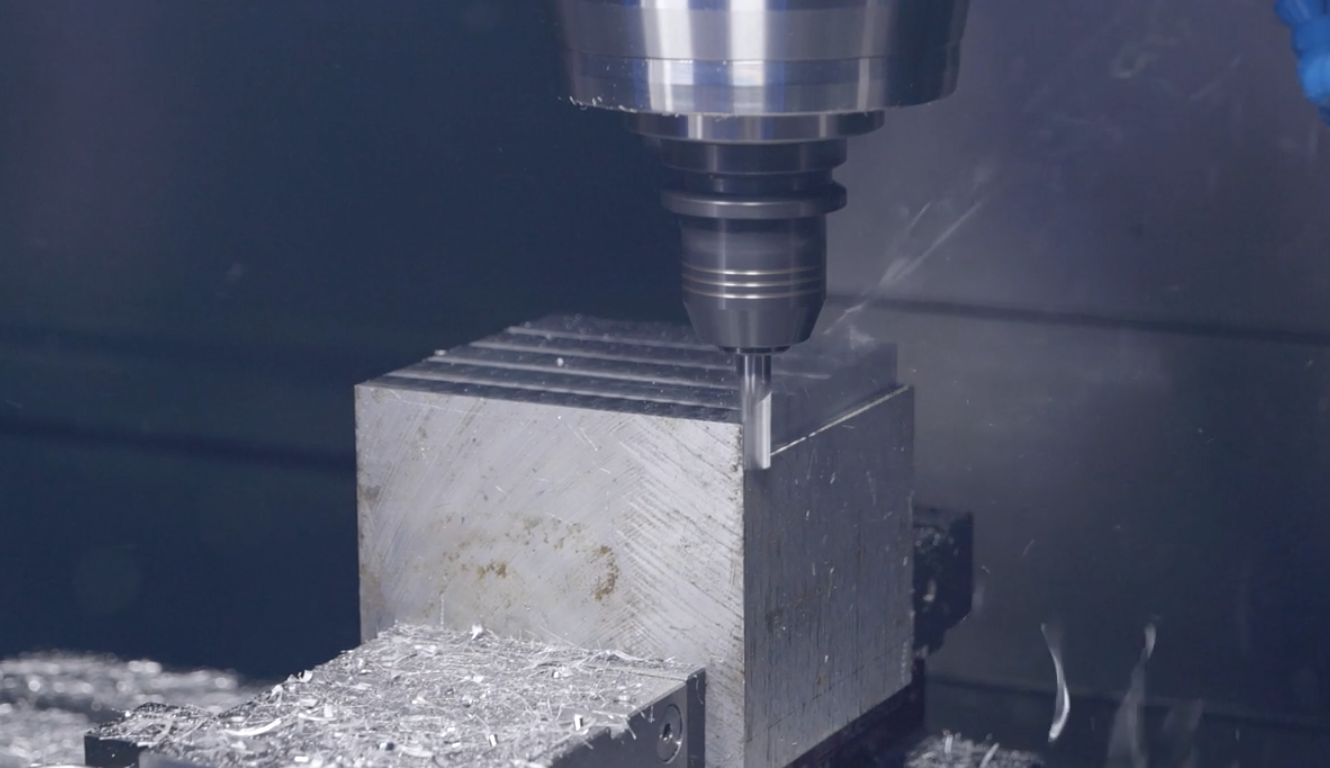

Ultra-precision machining comes with its own set of issues – the need for high mechanical rigidity, extremely high spindle speeds, optical sensor processing and correct tooling. Shibaura Machine has proved that by introducing, developing and implementing new technologies and techniques as they are conceived, future possibilities appear endless.

Shibaura started working on high precision machining in-house as far back as 1977, experimenting with aerostatic spindles, crystal diamond tooling and controlling the influences of temperature variations. By 1981, they had produced optical mirror finishes on parts for scanners used on laser printers. The introduction of magnetic heads for computer disks, requiring accuracies of 0.3µ whilst slow creep grinding, resulted in the use of built-in induction motors on a slicing machine, with 1,200 units delivered in the first 6 years of its introduction. The newest models meet the demanding accuracies required for producing V-grooves in 5G substrates.

For more information on the Gruppo Parpas range visit – www.leadercnc.co.uk/Parpas or for information on Shibaura Machine tools visit – www.leadercnc.co.uk/shibaura

Both brands are available in the U.K. from Leader CNC Technologies and don’t forget to follow us on Linkedin, Facebook and Twitter.

Linkedin – www.linkedin.com/company/leader-cnc-technologies

Facebook – www.facebook.com/Leader-CNC-Technologies

Twitter – www.twitter.com/LeaderCNCTech

We are pleased to announce that MTDCNC filming on the Gruppo Parpas’ stand is coming very soon. Don’t miss out subscribe to Leader CNC Technologies YouTube channel – www.leadercnc.co.uk/shibaura