🎧Wire EDM takes off at Blade Toolingire EDM takes off at Blade Tooling

🎧Wire EDM takes off at Blade Toolingire EDM takes off at Blade Tooling

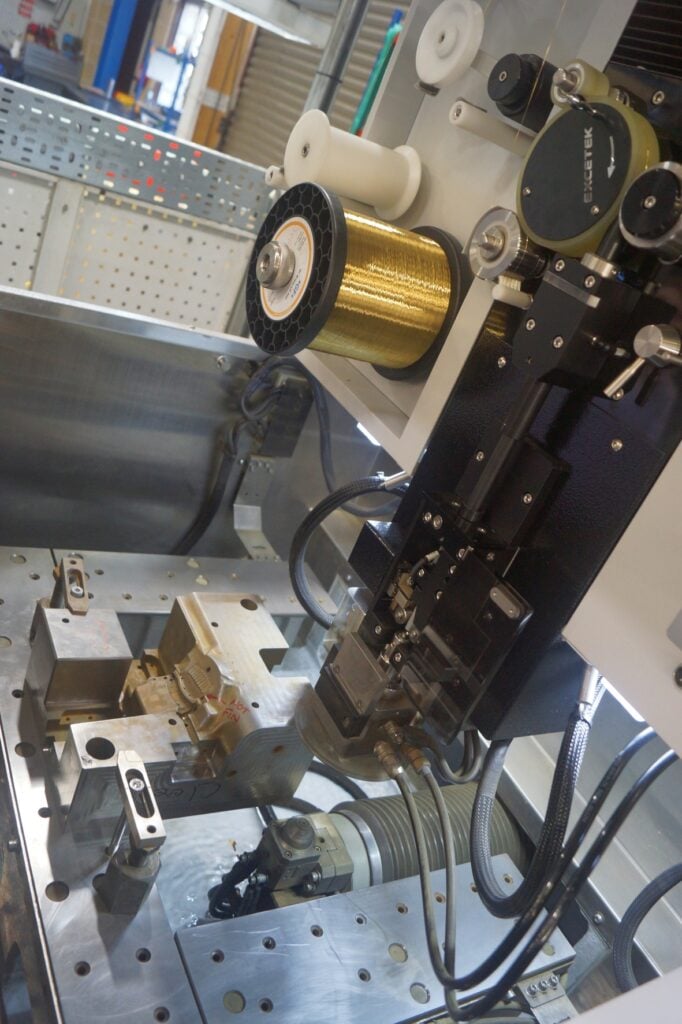

Blade Tooling, based in Pershore, has recently taken control of its wire-cutting EDM operations by investing in the Excetek V400G CNC wire EDM machine, supplied by Warwick Machine Tools. This decision was prompted by capacity shortfall that resulted in reliance on outsourcing for wire EDM services.

Established over four decades ago, Blade Tooling began as a family-owned business specialising in lost wax pattern dies for the investment casting industry. After financial difficulties in 2011, it was acquired by Gardner Aerospace, supporting aerospace manufacturers including Rolls-Royce, Pratt & Whitney and Siemens.

However, in 2017, Gardner Aerospace’s acquisition by a Chinese company created challenges. Company Director Ian Cerrone explains: “Because of what we do to support cast turbine blade production, a lot of customers walked away. They did not want their intellectual property potentially shared with China. The perceived risk was there, and our order book suffered.”

Sales dropped from £6m to £3m by 2022. Following negotiations, Blade Tooling became part of GIL Investments in March 2024. “Previous customers have come back and we have signed nine new NDAs in the last 12 months. We are now UK-owned, and former concerns have been removed,” says Cerrone.

With new ownership came investment. “We were spending a lot on subcontract wire eroding. I said to the new owner, ‘For what we’re spending, we could buy our own machine.’ The answer was, ‘Well, why haven’t you then?’ It was quite refreshing,” Cerrone reflects.

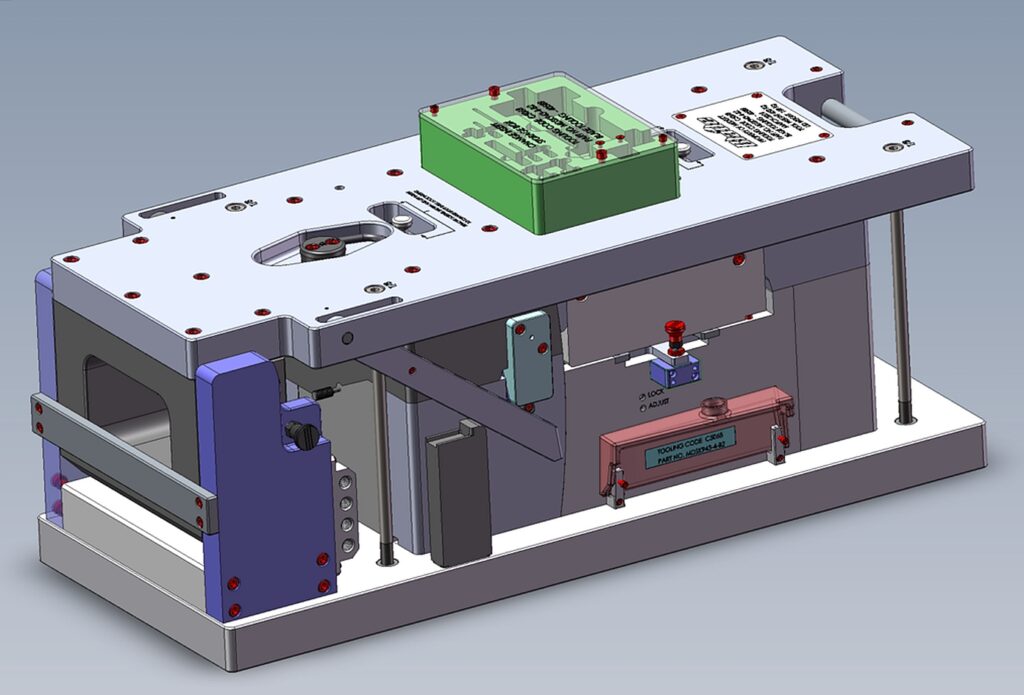

Blade Tooling relies heavily on CNC wire erosion for core tooling, essential for creating sacrificial ceramic cores that form intricate airflow paths within cast turbine blades. The hardened tools require wire erosion to create holes for pins, apertures, slots, and slides.

“We had to send work to subcontract wirers because we didn’t have capacity,” Cerrone recalls. After researching Excetek machines and noting positive reviews, he contacted nearby Warwick Machine Tools in Droitwich. A demonstration at their showroom proved the Excetek V400G was perfect for Blade Tooling’s requirements.

With 400 by 300mm travel and ability to accommodate workpieces up to 500kg, the machine offers versatility in a compact design. The standout feature is its auto wire feed. “All reviews stated the auto wire feed was unbelievable. The machine never stops, it just keeps feeding. Our other machine is forever stopping overnight,” says Cerrone.

The new machine has given Blade Tooling control over production schedules. Previously, subcontracting left them reliant on others. “We’ve had jobs scrapped due to delays. If the promised delivery by Monday arrived Friday, those four lost days would have put us behind on tight lead times.” Now, with doubled capacity, they control their timeline.

Looking ahead, the company is expanding from 35 to 45 staff and aiming to return to £6m turnover. Cerrone concludes: “What we make relies on high-end engineering. Every person here has pride in what they do, and everything is bespoke. Our people rely on the equipment we invest in, and we are very pleased to have installed the Excetek V400G.”