Manufacturer of CNC machines since 1840 and available in the UK from McDowell Machining Technologies, WaldrichSiegen is a prime example of sustainability due to the company’s ability to adapt to changes by investing in new, innovative technologies. Moving from the era of the steam engine to Industry 4.0, the company has maintained its core DNA.

WaldrichSiegen is defined by two words: accuracy and performance. The company specialises in large machine tools and its customers are mainly manufacturers of heavy marine engines, crankshafts and turbine rotors – that are increasingly demanding. That’s why WaldrichSiegen has invested in future-oriented technologies such as NC simulation with VERICUT to not just meet the needs of its customers but to surpass them. For them, the use of VERICUT software makes it possible to be more efficient and profitable from the start.

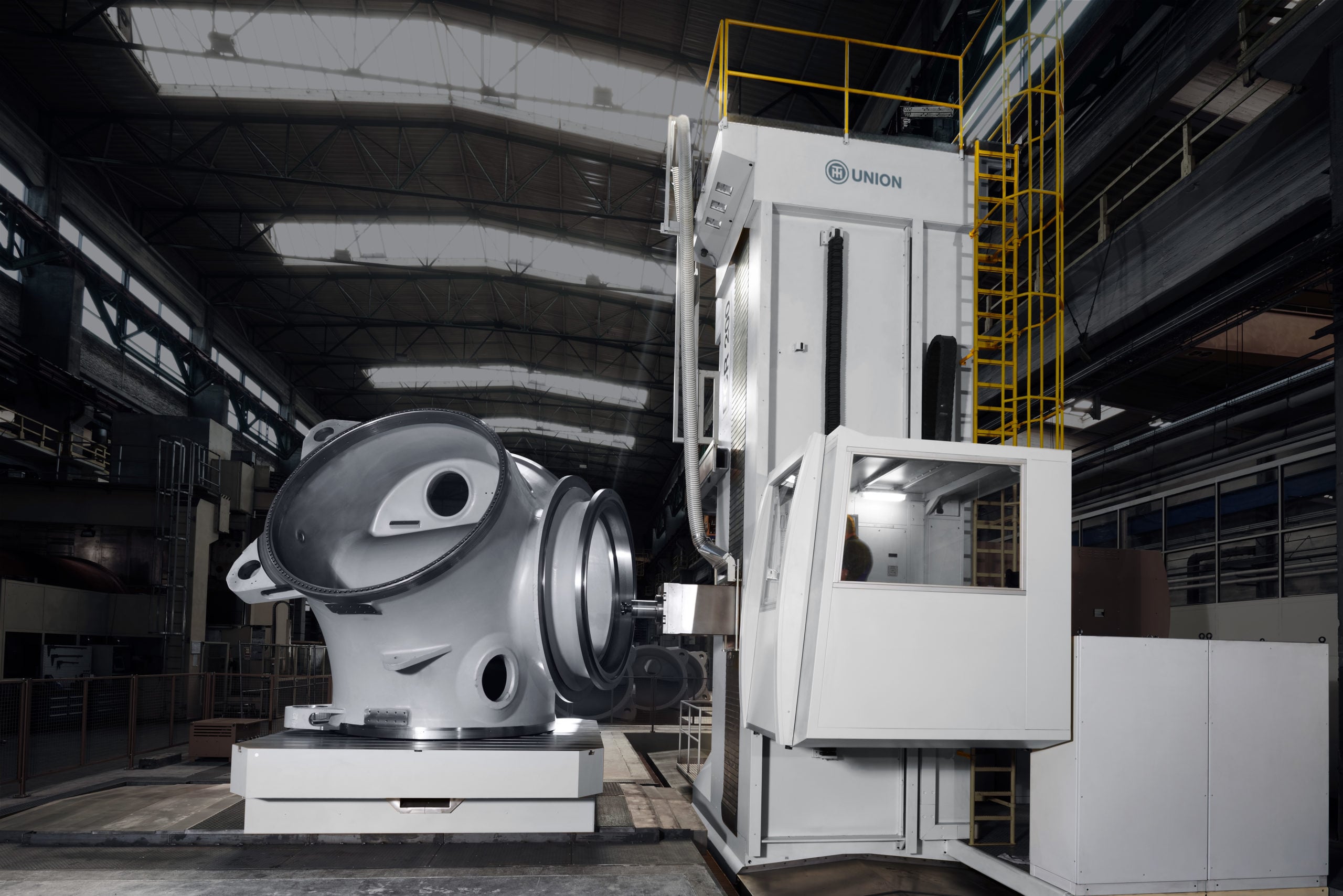

The largest machine in the world is built in Burbach

Since 2009, the 350 employee company has been using VERICUT for CNC simulation, G-code verification and optimisation. With the production simulation of the NC data, i.e. the machine code, WaldrichSiegen recreates the real machining situation with a ‘virtual processing machine on the desk’. This is done before even cutting the first chip. VERICUT simulates the original NC G-code after the post-processor is executed. This then detects program errors such as fast-forward errors or contour violations before any actual manufacturing.

“With VERICUT, machine collisions can be avoided, complex clamping situations can be safely retracted or cycle times can be reduced while at the same time increasing tool life,” says Christian Apel, Sales Representative of CGTech Deutschland GmbH.

This is particularly appreciated in large-scale machine tool construction, where process reliability is the be-all and end-all. To grasp the significance of error-free machining, it is worth taking a look at the key data of the world’s largest horizontal lathe, built after the customer’s ‘Go’ in 2009 at WaldrichSiegen. The machine has a 7m turning diameter, 25m workpiece length and more than 350 tonnes maximum workpiece weight. Previously, the company produced a lot of waste and had to do endless machining tests. Today, VERICUT makes it possible to safely speed up NC programs, improve part quality and reduce machining times.

More streamlined processes, better products, happier customers.

WaldrichSiegen not only uses VERICUT simulation software to streamline its manufacturing processes but that of its customers too. Indeed, the company wants to use digital transformation and its integral elements such as the digital twin in VERICUT, to develop new fields of activity and to transfer real added value to customers.

For example, by integrating customers and partners into the company’s value creation processes at an early stage. Timo Hees, an Application Technician at WaldrichSiegen, says: “When a customer orders a machine, we often carry out studies upstream so that we can determine and evaluate subsequent machining times at an early stage.

“It’s well thought out and well done. WaldrichSiegen simulates the customers’ machining in VERICUT, to demonstrate the machining and process times for the customer’s parts, even before the actual machine is installed at the customer’s premises. This makes it possible to make valid business decisions at all levels.”

Timo Hees explains: “VERICUT is an integral part of the project. The machine is then made available to the customer with the kinematics developed in collaboration and tested by WaldrichSiegen. This is the only way to ultimately guarantee that all functions can be performed appropriately so that the customer can already perform their simulation and check internally in VERICUT if everything is in line with what they had planned.”

“It’s in the millions, which is why we only have one trial.”

According to management member Stefan Tschersche, the advantage of such an approach for WaldrichSiegen’s customers is obvious: “With VERICUT, we ensure that the machining is simulated beforehand as close as possible to reality to avoid damaging the part and the machine.”

Collisions would also be fatal given the size of the part and the machine tool. Stock material alone can cost several hundred thousand Euros, sometimes more. “This can go up to several million, which is why we often only have one test,” confirms Stefan Tschersche.

The large machine tools at the Siegen production site are used, among other things, in the production of diesel engines, cogeneration plants, turbines, general mechanical engineering, the energy sector as well as in defence and nuclear.

Decades of experience to develop high-performance solutions.

WaldrichSiegen draws on decades of experience to develop high-performance solutions that are perfectly suited to a wide range of applications. WaldrichSiegen is part of the HerkulesGroup, which has more than 1500 employees worldwide. A specialist in the development and production of large machine tools, it offers its customers complete high-precision machining to make the most complex parts. Beyond all the performance data, HerkulesGroup’s companies also offer customers absolute added value with their machines, considering life-cycle costs from the moment of construction. Thus, the machines are energy efficient, easy to maintain and repair, and are of the highest quality down to the smallest detail.

For more than 180 years, WaldrichSiegen has known that continuous innovation is needed to create industry-leading trends. Currently, the company is showing great interest in using the FORCE module. WaldrichSiegen wants to optimise the processing times of its clients’ complex projects. FORCE is a physics-based NC program optimisation software module that analyses and optimises cutting conditions throughout the NC program. It provides the most efficient NC program based on material, cutting tool and machining conditions. These results are considerable time savings and improved cutting tool life.